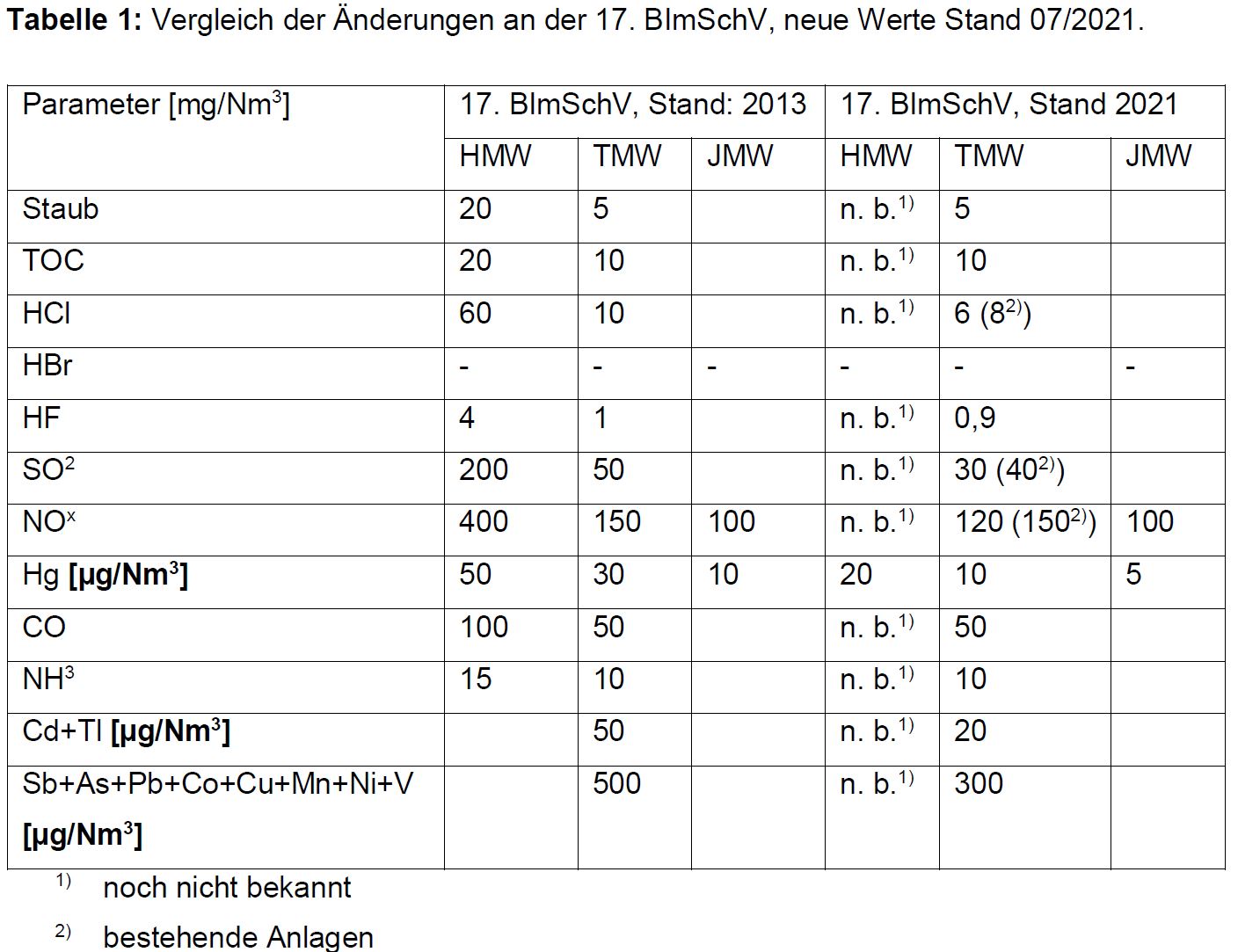

As a result of the amendment to the 17th BlmSchV and the TA Luft, tighter emission limits will apply in some cases from mid-2022. (See Table 1 and Table 2). This makes retrofitting or at least the verification of flue gas cleaning necessary at some waste to energy plants.

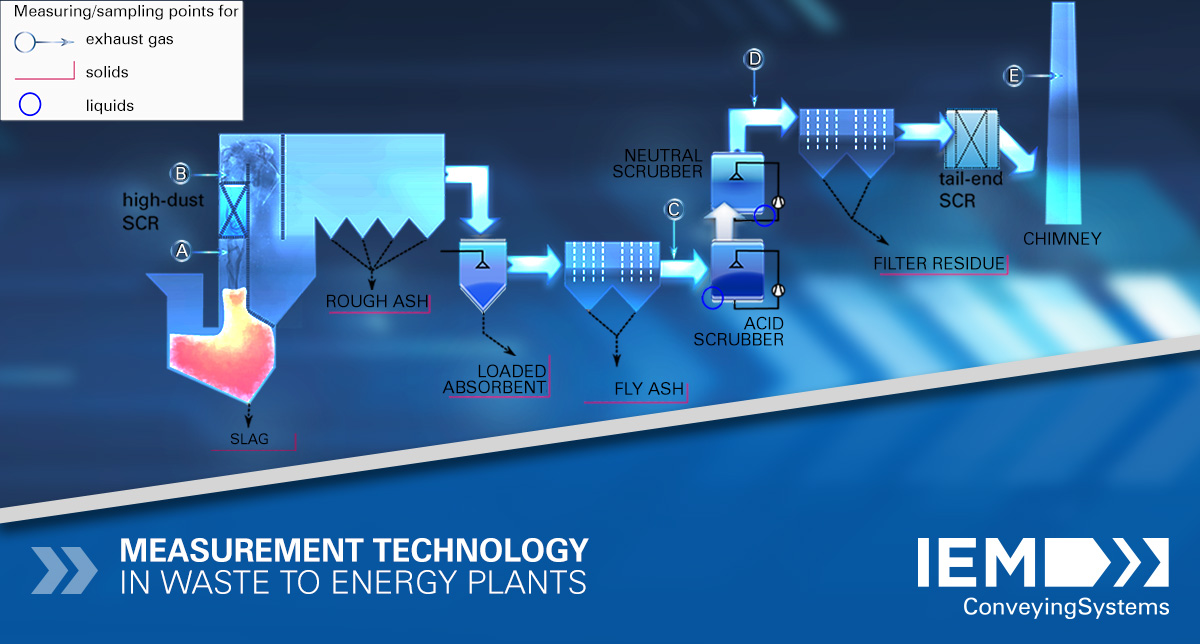

IEM offers measurement technology and evaluation of the current separation performance:

- Hg species measurement in waste gas (if required also HCI, HBr)

- Sampling of various material streams

- Preparation of material balances and complete metrological support from a single source

- Execution of controlled load tests of the separation plant (e.g. by addition of so-called Hg-bombs)

- Recommendation of possibilities for emission reduction based on the data from a material balance, a load test and/or empirical values

- Complete documentation of the results

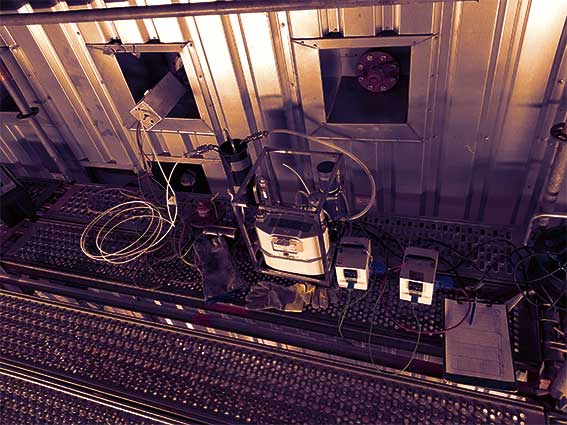

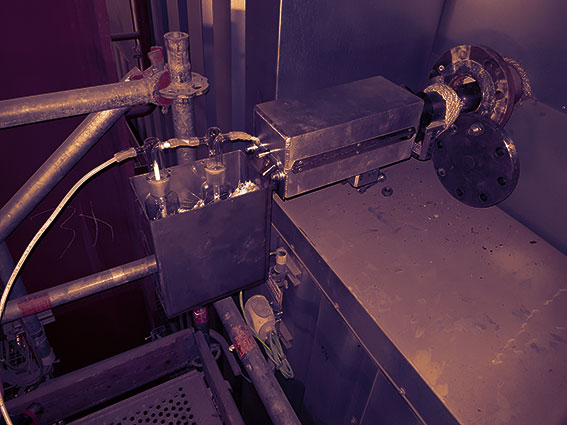

Depending on the parameters to be determined, the parameters in the exhaust gas are measured using adsorber tubes based on the US reference method M30B or by using bubblers (see picture 5)

To determine a material balance, measurements are carried out on the input and the various output streams of the plant components in order to record the separation of conversion efficiency. This results in an evaluation of the individual plant components, and starting points for an efficient reduction of emissions can be determined and defined.

Furthermore, in the field of emission reduction, IEM offers complete packages including preparation, implementation and evaluation:

- Addition of halides to the firing

- Use of the AK entrained flow method

- Addition of additives to wet scrubbers

- Fixed bed catalysts (partial bypass)

- Further abatement processes on request

For most of these reduction measures, our own equipment is available; waiting times or delays due to external procurement or commissioning are eliminated.

Benefit from a full-service solution for measurement, sampling, balance preparation, full metrological support, consulting and documentation!