References Here are some references that were served to our company.

Barrel Testing System

For the inspection of nuclear barrels with low-level radioactive waste for transport to the Konrad repository, IEM FörderTechnik manufactured a mobile barrel tipping system.

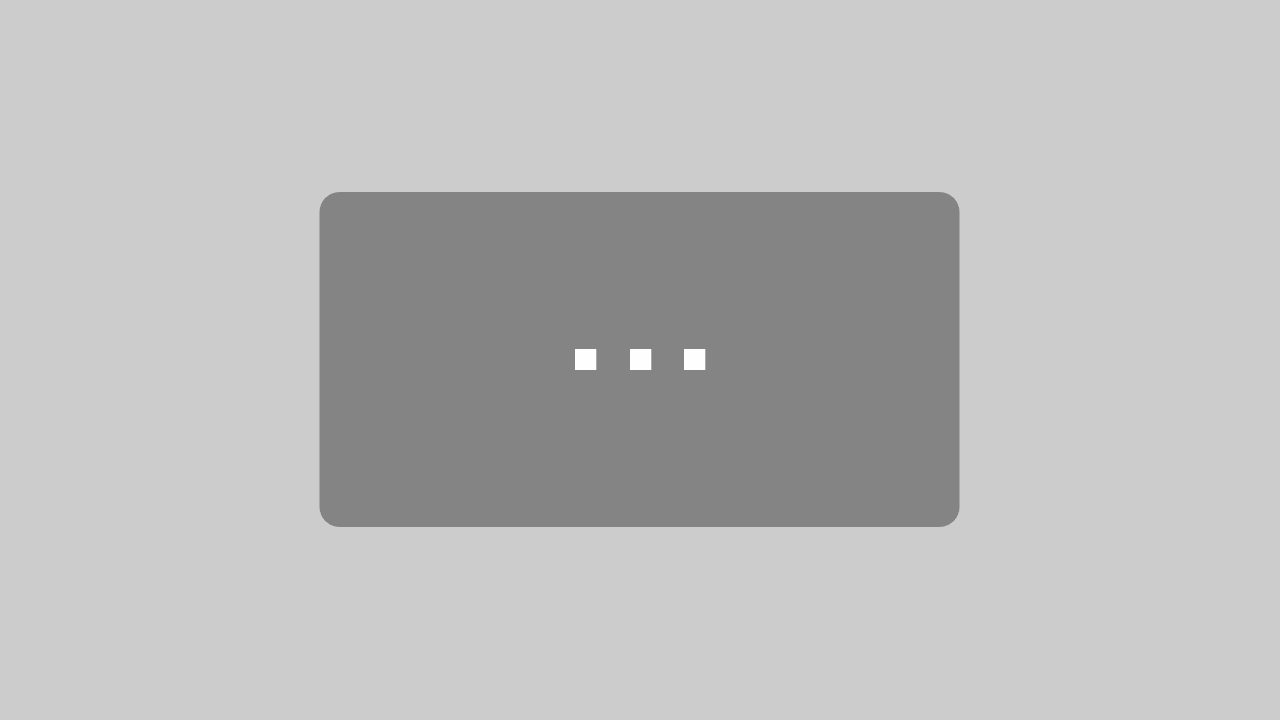

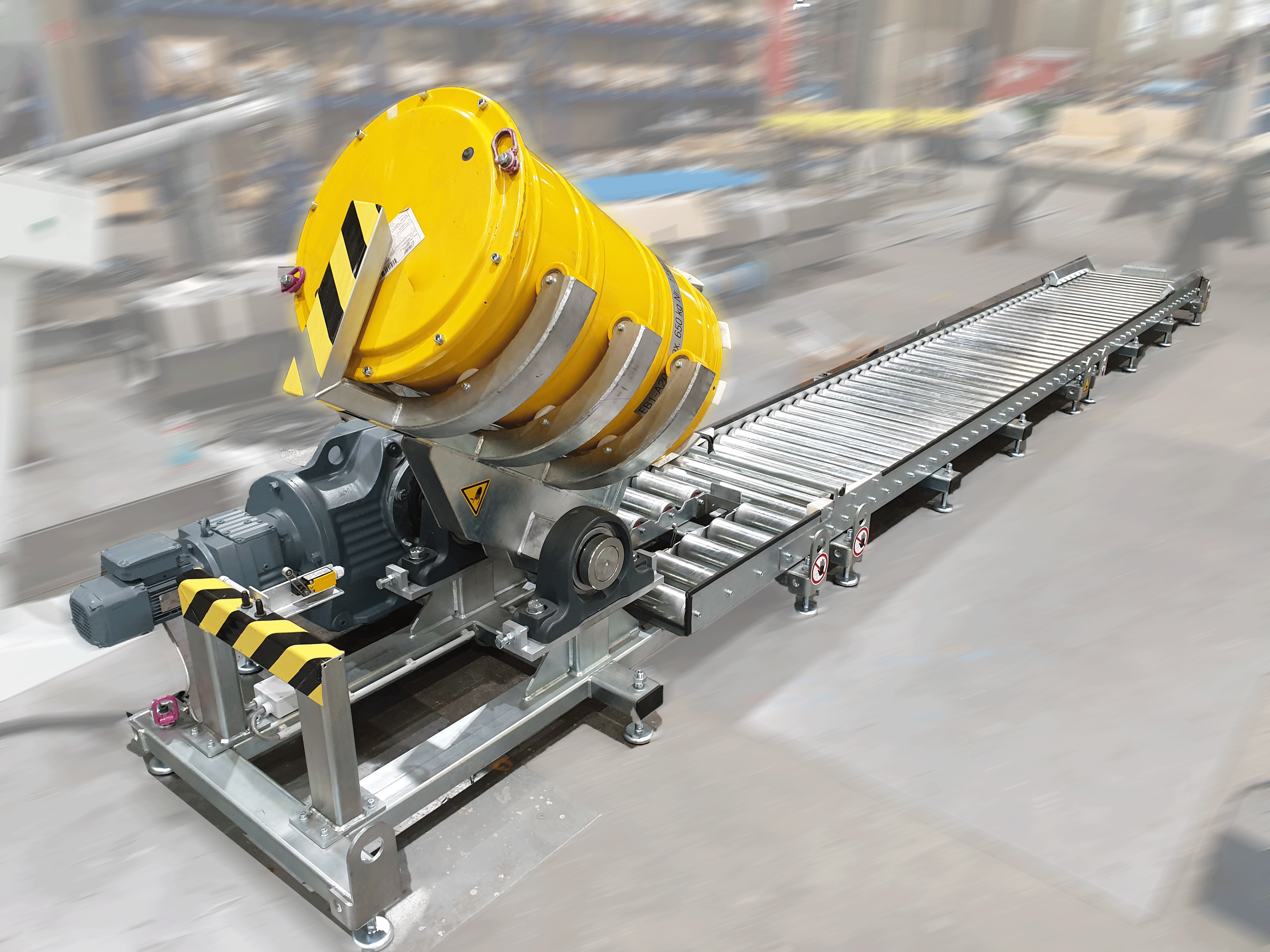

Barrel Tipping System

For the decommissioning of a nuclear power plant in Germany, IEM FörderTechnik GmbH manufactured a mobile barrel tipping system with upstream roller conveyor segments and two driven roller conveyors with integrated drum tilting device. The barrels with low-level radioactive waste are pre-buffered with these systems before being stored into containers supported by handling equipment.

Residual Material Handling

For a reprocessing plant for radioactive material in China, IEM FörderTechnik GmbH manufactured driven roller conveyors, raiseable and lowerable chain conveyors and turntables.

IEM FörderTechnik GmbH also carried out the on-site delivery and installation.

Airlock with Radiological Monitoring

For the decommissioning of a nuclear plant in Germany IEM ConveyingSystems GmbH manufactured an airlock with integrated radiological monitoring and conveying technology.

Pre-measured containers are taken over by the semi-automatic system and scanned for radiological issues. If theradiological value falls below the specified limit the container is released and automatically discharged from the controlled area into the monitored area.

An Alloying Agent System

For the modernization during the ongoing operation of the secondary metallurgy of an alloying agent plant in Germany, IEM FörderTechnik GmbH planned, manufactured, delivered and installed the feed to the furnaces and scrap basket, corrugated belt conveyors, skip belt conveyors, truck acceptance bunkers and steel construction.

Customer: SMS Siemag, Düsseldorf

Commissioning: 2011

Planning: detail engineering, production, assembly IBN

Material: dolomite, lime, coal, manganese, alloying agent

Performance: 150 – 333 Mg/h

Location: Peine

Scope:

Filling furnaces and scrap basket,

8 silos and 16 daily bunkers,

40 pcs. of conveyor channels,

2 pcs. corrugated belt conveyors,

15 pcs. troughed belt conveyors,

2 truck acceptance bunkers,

steel hall construction

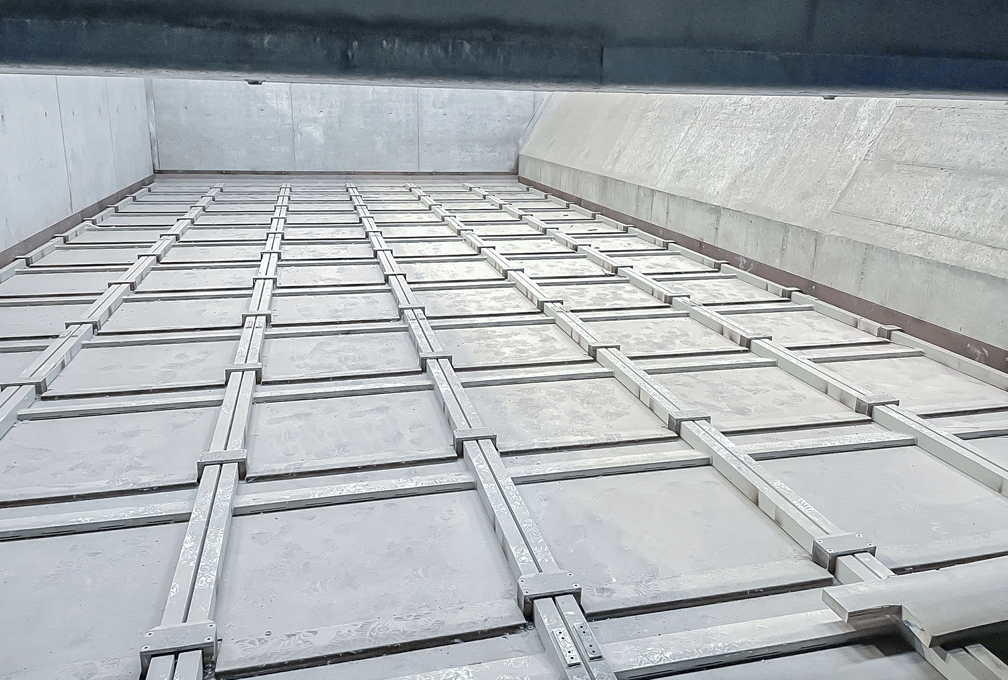

For a biomass power plant in Braunschweig, IEM delivered two hydraulic push floor discharge systems in 2022. These systems are built with heavy welded constructions and wear-resistant floors and were installed on the customer-provided foundation. The push floors are moved by hydraulic cylinders, which are installed opposite the floor discharge opening. The associated hydraulic units are located below the cylinder fixed points in a separate room. Both push floor systems can operate independently and achieve a full throughput capacity of 150 m³/h each. Additionally, parallel operation with a total capacity of 300 m³/h is also possible.

Customer: BS Energy, Braunschweig

Commissioning: 2022

Material: Biomass

Location: Braunschweig

Dimensions of Push Floors: 7,000 x 15,000 mm and 7,000 x 18,000 mm

Scope: 2 hydraulic push floors: 7,000 x 15,000 mm each installed on six tracks

Conveying Capacity: 150 m³/h discharge capacity each with a conveying density of (volume) 0.2 t/m³ or a static design density of 0.4 t/m³ for the discharge of waste wood.

Biomass Cogeneration Plant CHP in Brunswick GER

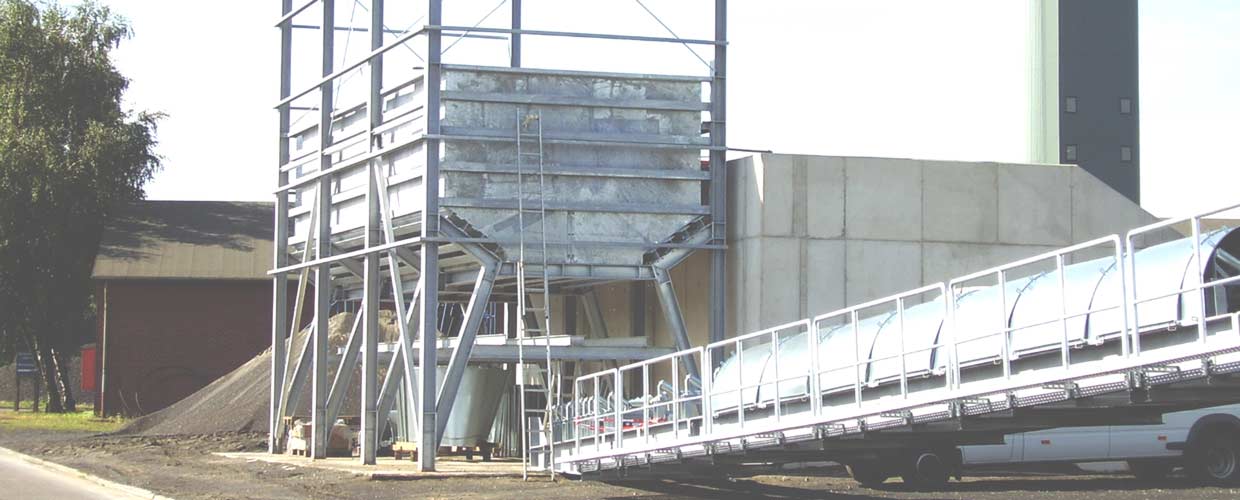

The biomass coal-fired power plant is connected to the warehouse by a 70-meter-long conveyor bridge.

This will be used to transport the waste wood in the future. The conveyor bridge, which weighs over 200 tons, consists of two parallel lines, each with a conveyor belt. It was mostly preassembled in two individual parts and then lifted into place with two mobile cranes.

Planning: Detail engineering, manufacturing, installation and commissioning

Conveyed Material: Waste wood

Capacity: 2 lines à 60

Location: Brunswick

Location: Peine

Scope of supply: One conveyor bridge consisting of two parallel lines, each with one conveyor belt:

- 2 Pull Floor systems

- 2 Trough Chain Conveyors

- 2 Troughed Belt Conveyors

- 1 Tube Chain Conveyor

- 2 Belt Scales

- 2 Cleaning Scrapers

A Cogeneration Plant

For the modernization of a 900MW coal / biomass cogeneration plant in the Czech Republic, IEM FörderTechnik GmbH manufactured, delivered and installed transfer towers, conveyor belts, metal detectors, band bridges, corrugated belt conveyors, and drive units.

Customer: Kraftanlagen München

Location: Kladno (CZ)

Scope:

4 transfer towers

7 conveyor belts

various metal detectors

multiple power units on top of the transformers

a vacuum line system

a spraying system

freight, assembly, INBN

Bucket Elevators

Here you can view some of the bucket elevators designed, constructed and converted by IEM FörderTechnik GmbH .

Troughed Belt Conveyors

Here are some troughed belt conveyors – designed, constructed, and converted by IEM FörderTechnik GmbH.

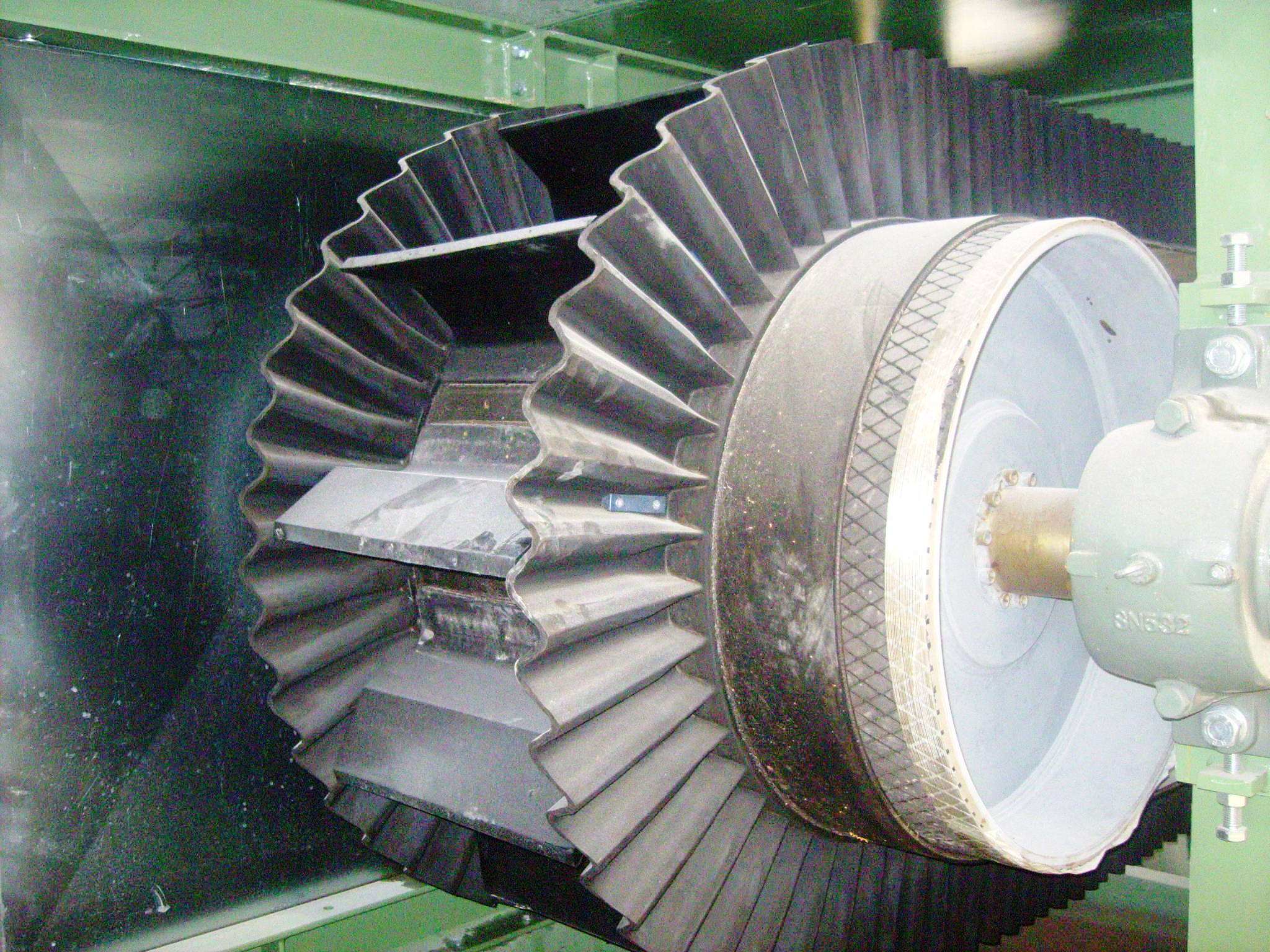

An Abrasive Blasting System

IEM FörderTechnik GmbH as a general contractor, created a new abrasive blasting system from the upper edge of the basement ceiling for a blasting abrasive manufacturer in Germany.

Here, slag from the power plant is transported via conveyor belts to the installation where it is dried, crushed, sieved into commercial fractions, packaged and loaded.

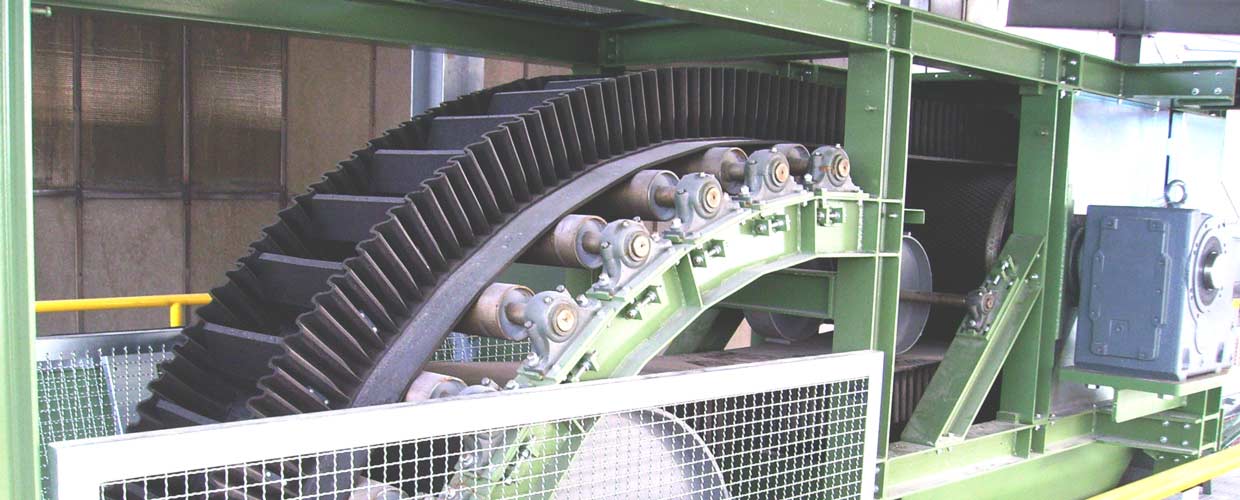

Corrugated Belt Conveyors

Here are some examples of corrugated belt conveyors – conceived, designed and implemented by IEM FörderTechnik GmbH.

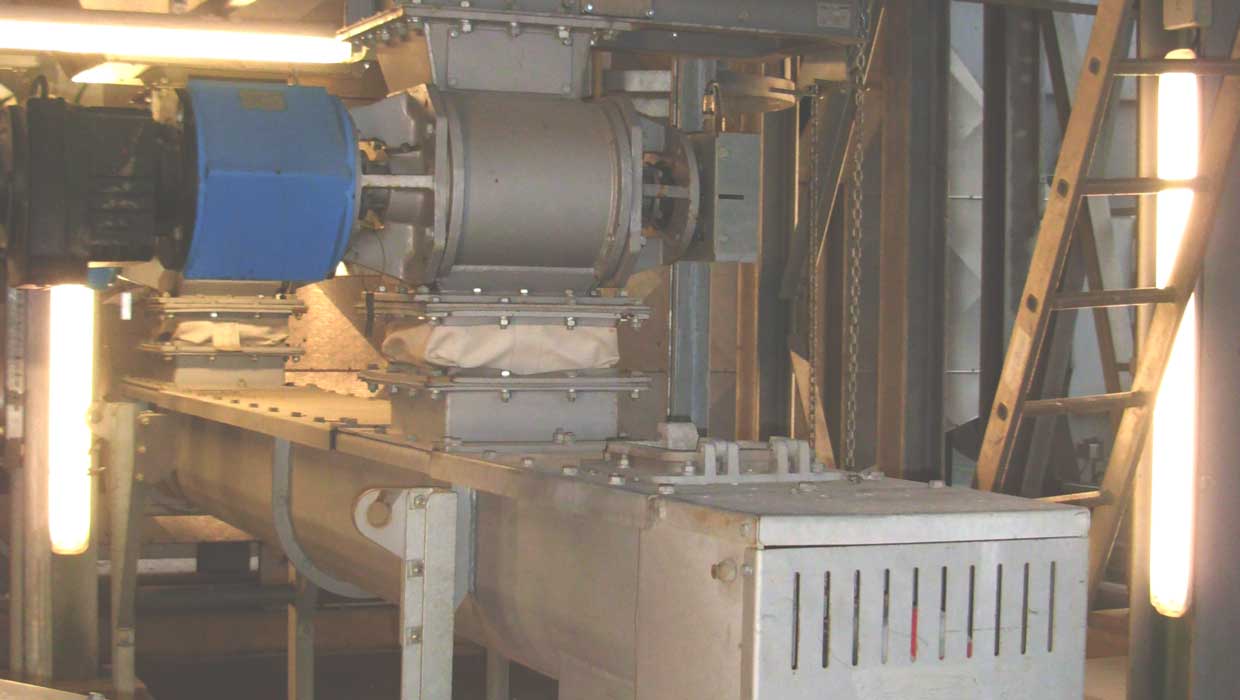

Screw Conveyors

Here is an example screw conveyors – conceived, designed and implemented by IEM FörderTechnik GmbH.

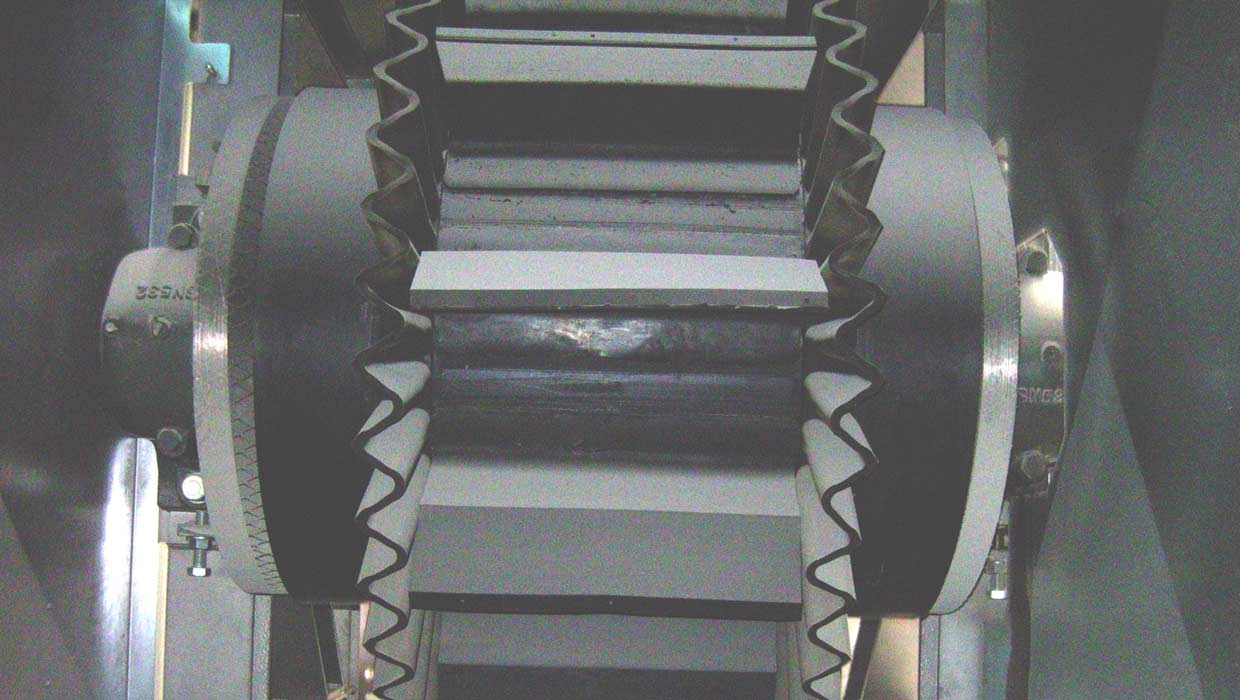

Troughed Chain Conveyors

Here are some examples of troughed chain conveyors – conceived, designed and implemented by IEM FörderTechnik GmbH.

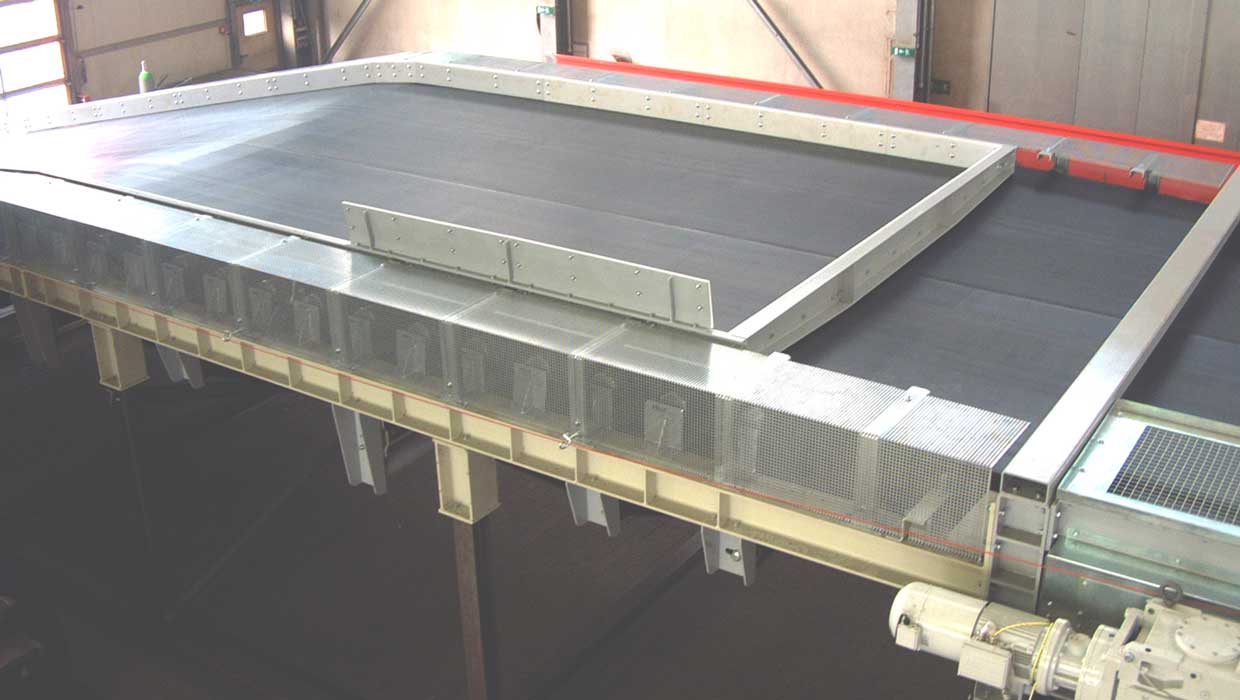

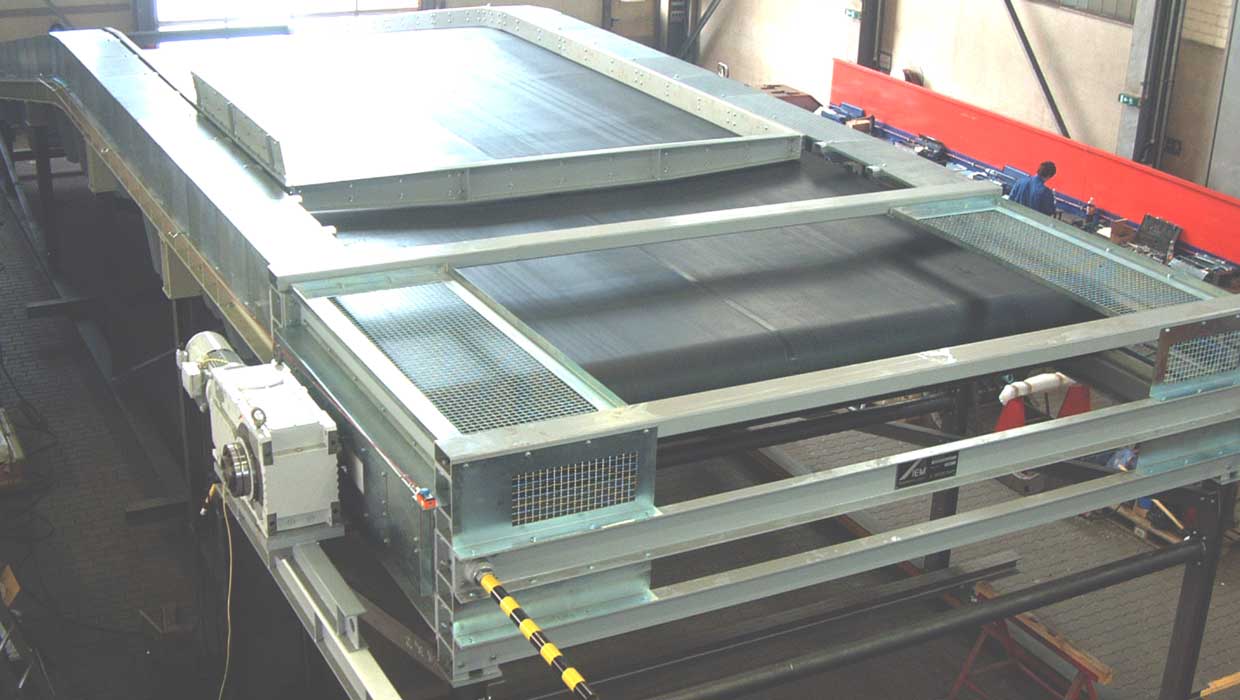

Wide Belt Conveyor

Here are some examples of troughed chain conveyors – conceived, designed and implemented by IEM FörderTechnik GmbH.