IEM FörderTechnik GmbHProducts and Plant Solutions in

Material Handling Technology

IEM Födertechnik GmbH offers products and services for the implementation and optimization of processes in material handling. For decades, we have been successfully designing, constructing and manufacturing for our customers.

Our major advantage is the connection between process and manufacturing know-how. Whether we are planning a new plant, improving a process or updating your existing technology, we always aim to satisfy our client. All components and systems are state-of-the-art and adapted to new requirements. We value each of our assignments as a sign of trust.

Products for bulk handling

RPODUCTS FOR UNIT LOAD HANDLING

Bucket Elevators

Bunkers

Container

Transfer

Systems

Ash Removal

System

Bottom Ash

Discharger

Box Feeders

Chain Belt

Conveyor

Coal Feeder

Mixing Screw

Conveyor

Troughed Belt

Conveyor

Reciprocating/

Wide Belt

Conveyors

Roller

Conveyors

Screw

Conveyors

Steel Plate

Conveyors

Trough Chain

Conveyors

Corrugated

Belt Conveyors

Hydraulic

Push Floor

Special Constructions

Bucket Elevators

For continuous vertical transport of fine to coarse-grained, free-flowing to cohesive, as well as poorly flowing bulk materials.

Specifications

- High flow rates up to 1,000 t/h or higher output upon request

- Vertical conveyor lines over 100 meters in space

- Minimal space requirement

- Absolutely dustproof, pressure shock resistant, and gas tight

- Feasible chain bucket elevators for hot goods transport up to 400 ° C

- Suitable for heavy and abrasive materials

- Low maintenance

- Low-noise and product-friendly transport

References

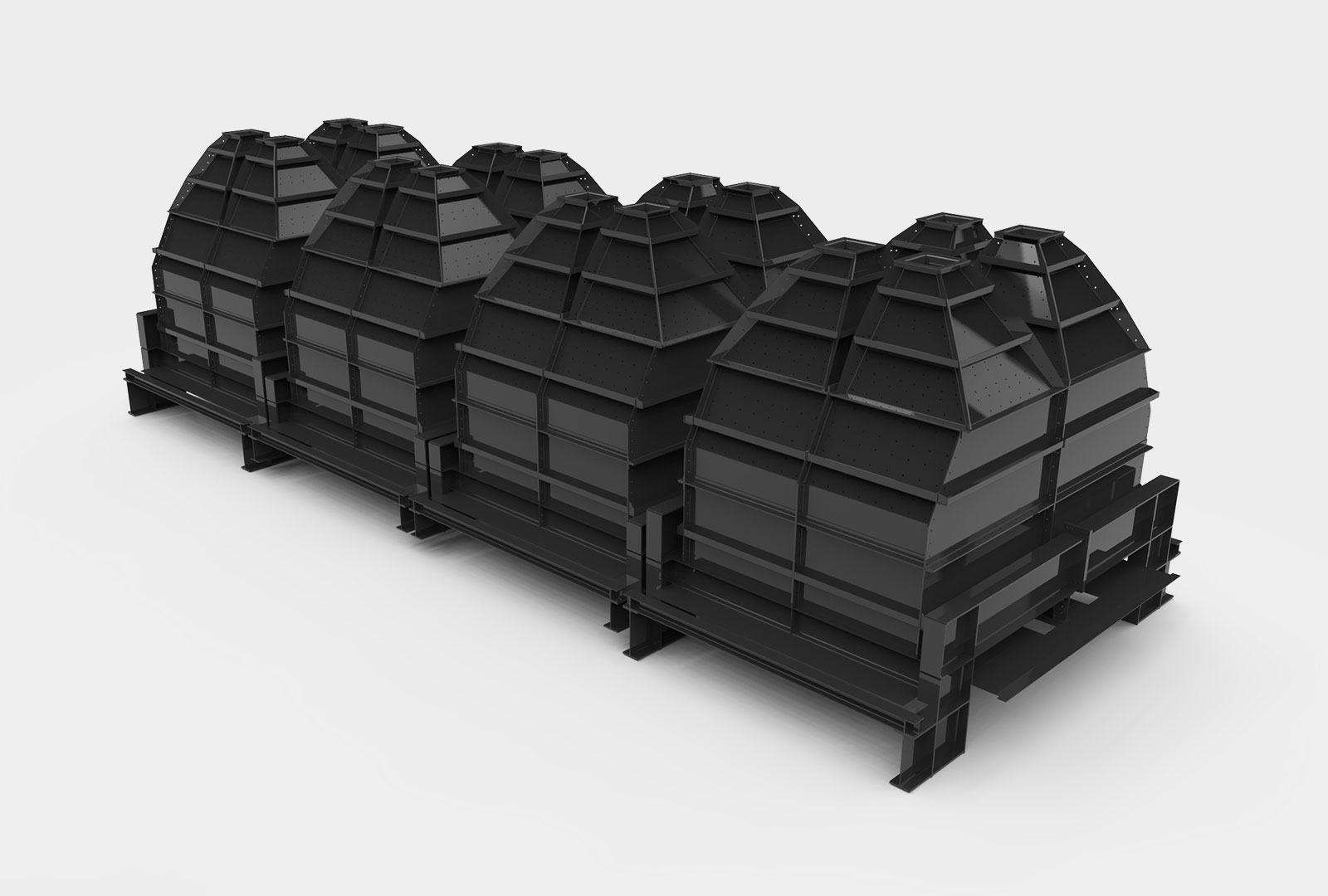

Bunkers

The IEM bunkers are tailor made for receiving and (intermediate) storage of various bulk materials. The IEM bunkers are designed according to your needs and perfectly matched to the infeed and outfeed conveyors.

References

Container Transfer Systems

An example of a container transfer system is used in the disposal of the waste. The required transport tasks are handled by means of roll-off containers over driven roller conveyors and transverse transfer tracks. In order for the production process to run smoothly, an empty replacement container is located on the transfer device and would automatically be exchanged for the full container if required – thus, only a small downtime.

Fortunately, even with space problems, the transfer system is suitable for both closed and open top containers. In addition, the filling position can be provided with a weighing device, which will ensure that the containers are not overcrowded.

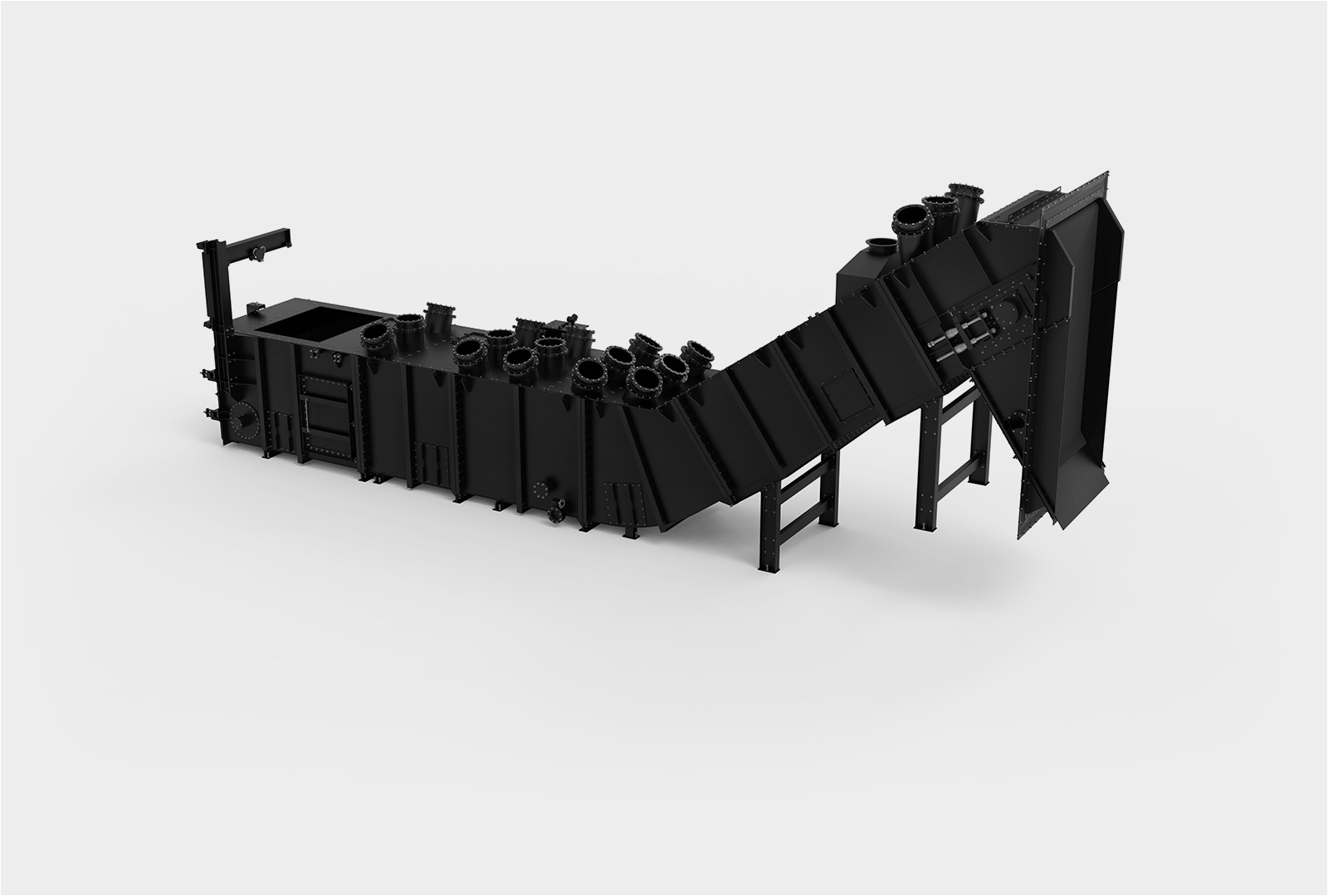

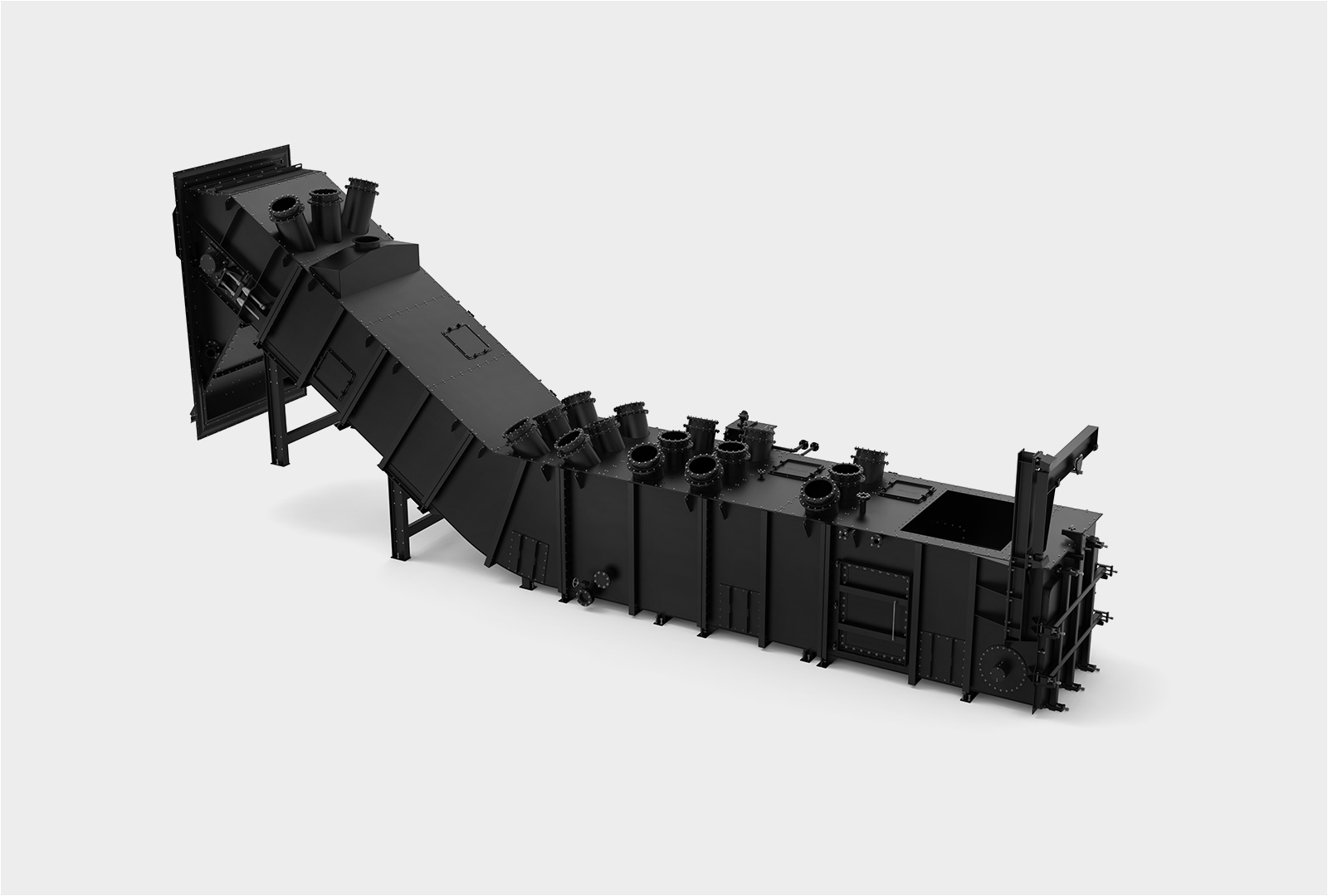

Ash Removal System /

Wet or Dry Bottom Ash Handling System

The IEM Ash Removal System and Deslagger have been designed for the reliable transport of combustion residues in power plants. Due to their special design, they are particularly suitable for use with secondary fuels. IEM FörderTechnik GmbH provides designs for wet or dry bottom ash handling systems, scraper conveyors or apron conveyors in waste-to-energy plants, EBS power plants, biomass power plants and coal-fired power plants.

Specifications

- Conveying speed: from 0.6 to 6 m/ min

- Throughput: up to 40 t/h

Box Feeders

Box feeders are used in a wide variety of industries, for example, in mining, foundries, steel mills, paper mills, scrap processing, in environmental and recycling plants. If necessary, box feeders can be used with a cleaning device.

The box feeder is used for receiving, purging and metering of biowaste and green waste, organic production residues, waste paper and plastic waste, garbage slag, sludge, tunnel waste, etc.

Specifications

- Storage Volume: 1 – 40 m³

- Belt Widths: 800 – 2.200 mm

- Delivery Capacity: 0.025 – 10 m/min

- Discharge Rate: 0.09 – 420 m³/ h

References

Chain Belt Conveyor

The IEM chain belt conveyors are used for receiving and feeding medium to heavy bulk or general cargo. The chain belt conveyor consists of a transport belt with screwed steel catches, mounted on cylindrical profiles which are located between two bush conveyor chains. The drive sprockets are connected by a shaft and are driven by a geared motor.

The IEM chain belt conveyor is available in multiple kinked versions.

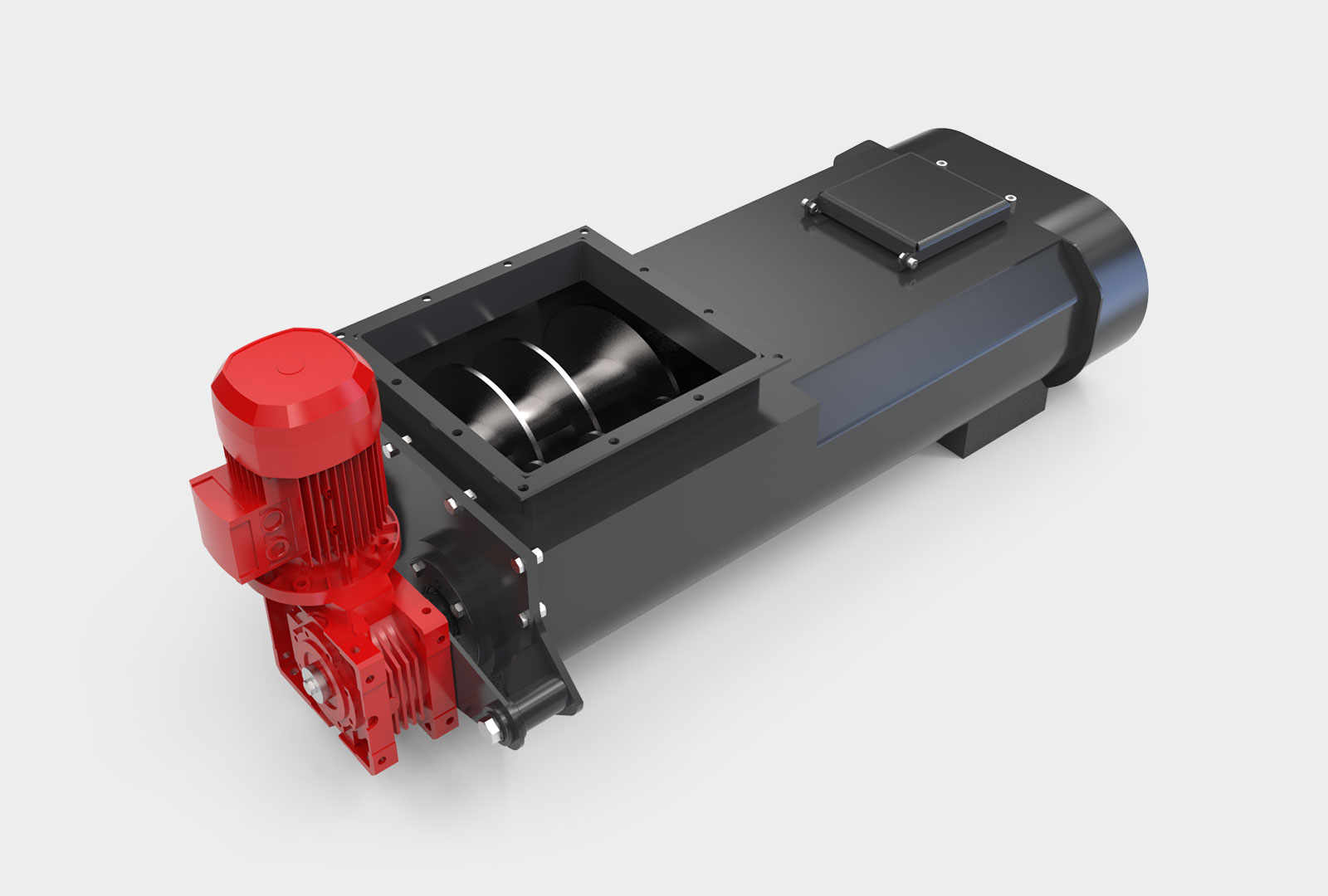

Coal Feeder

Used for transporting lignite and hard coal in power plants for mill feeding. The coal feeder is usually connected directly via a coal chute to the coal bunker with a rectangular outlet. Between the coal chute and the bunker outlet, a flat needle valve can be arranged as a shut-off.

Specifications

- Throughput up to 150 t/h

- Reduced pressure shock resistant in accordance with requirements

References

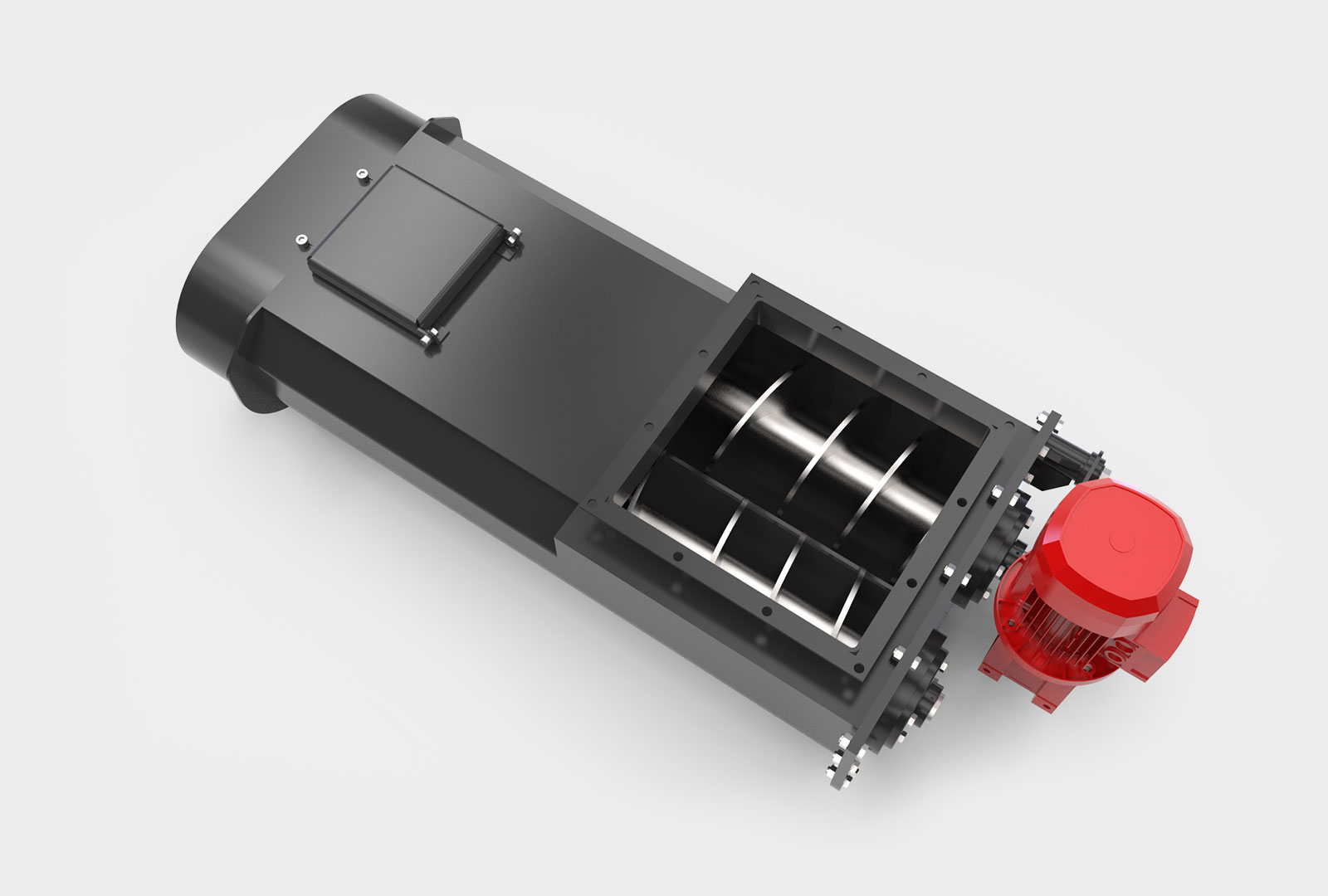

Mixing Screw Conveyor

Depending on the equipment, the mixing screw conveyor comes with various mixing tools in different industries, also may be used as a wetting screw. The following applications are possible:

- Mixing of dust, granules, powders, sludge and problematic substances, also in ATEX version

- Horizontal and oblique arrangement

Advantages:

- Absolutely dustproof, pressure shock resistant (as specified) and gas-tight

- Self-cleaning screws for caking and pasty substance

- Can be produced in special materials, lined

- Minimal space needed

- Low-noise material transport

- Low maintenance

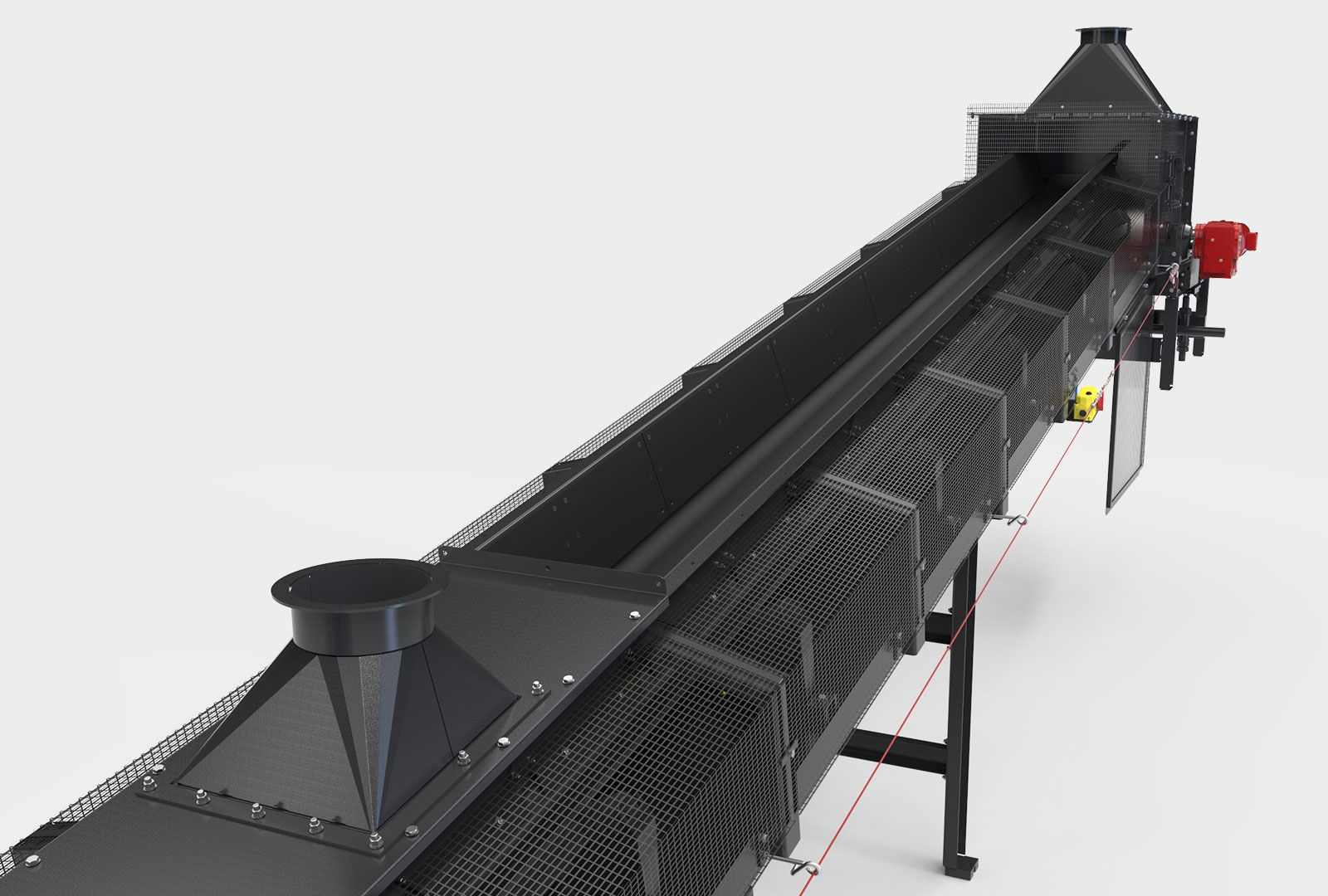

Troughed Belt Conveyor

The IEM troughed belt conveyors are often used for large flow rates that have to be transported over a long distance. The 2- or 3-part beaded belts are mainly suitable for heavy bulk goods with high throughputs. IEM combines the system with catwalks and strap bridges and offers them with irrigation, completely cased and de-dusted. The fields of application are the transport of minerals, such as coal, ores, slags, residues, sugar or beets, sewage sludge, foundry sands, recycling products, and alloying agents.

Reciprocating / Wide Belt Conveyors

The reciprocating conveyor adapts to the speed of the wide belt material conveyor and returns the defined amount of material in accordance with the desired layer height during the return movement of the carriage. During the extension movement no material is relinquished, as the belt speed of the reciprocating conveyor = extension speed. This procedure is recommended to ensure a consistent feed.

Specifications

- Wide Belt Throughput up to 1,300 t/h

- Belt width up to 5,500 mm

- Reciprocating Throughput up to 1,300 t/h

References

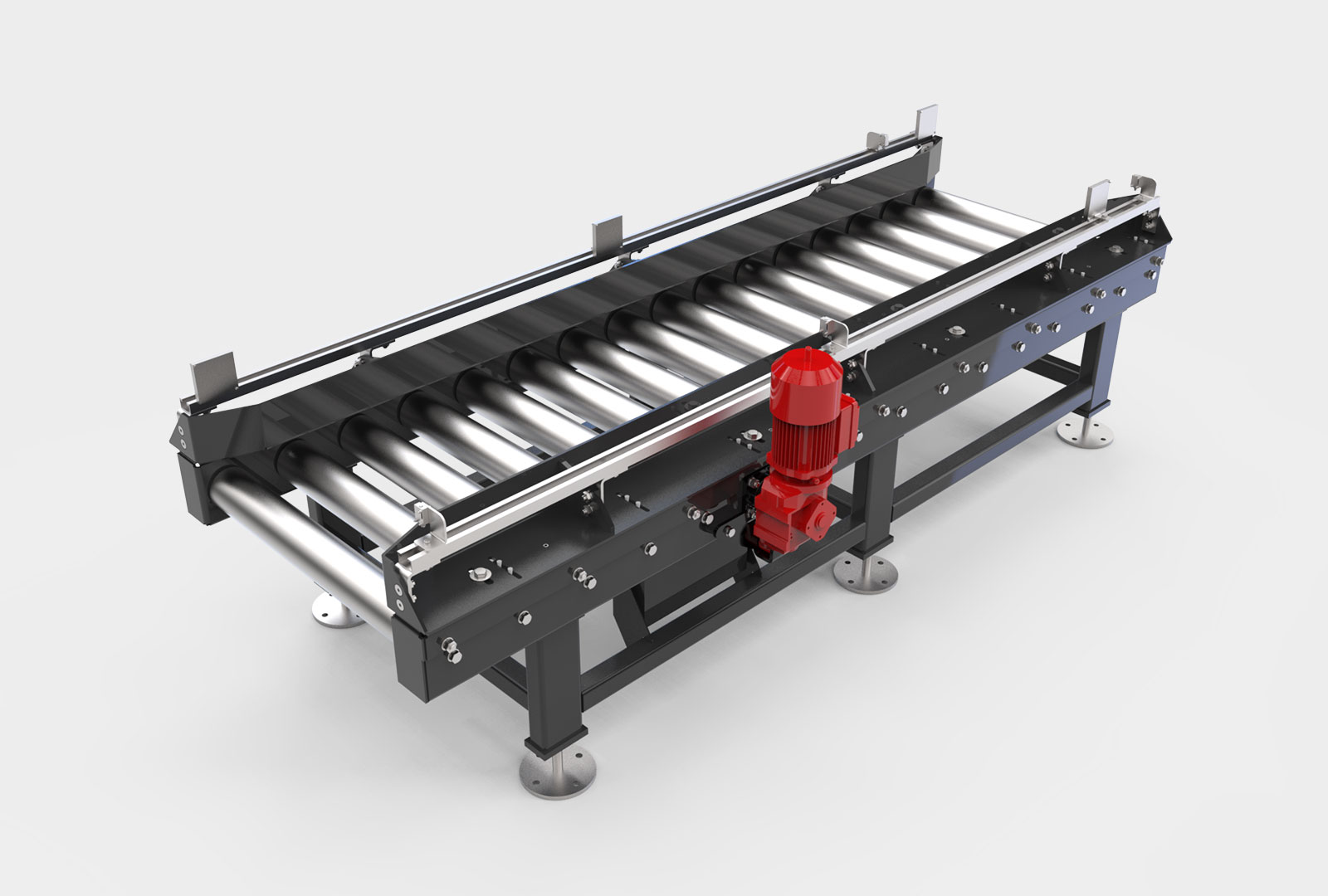

Roller Conveyors

For the in-house transport of light to heavy general cargo, such as feed and discharge tracks on machines and systems. Available as a driven roller conveyor, non-driven roller conveyor and curved track.

References

Screw Conveyors

IEM screw conveyors are used in the basic industry and power plants for sludge and ash transport. They are ruggedly designed for load-intensive continuous operation. IEM screw conveyors have been successfully successfully for decades to convey powdery, granular and semi-wet bulk material. In addition, they are also available in pressure shock resistant and in the ATEX version. The type of screw is possible – in accordance with requirements – as trough or pipe screw.

Specifications

- Flow Rates up to 1,400 m³/h

- Conveyor Length: up to 6 m/unit

- Conveying Speed: 0.05 – 1.5 m/sec.

- Diameter: 160 – 800 mm

References

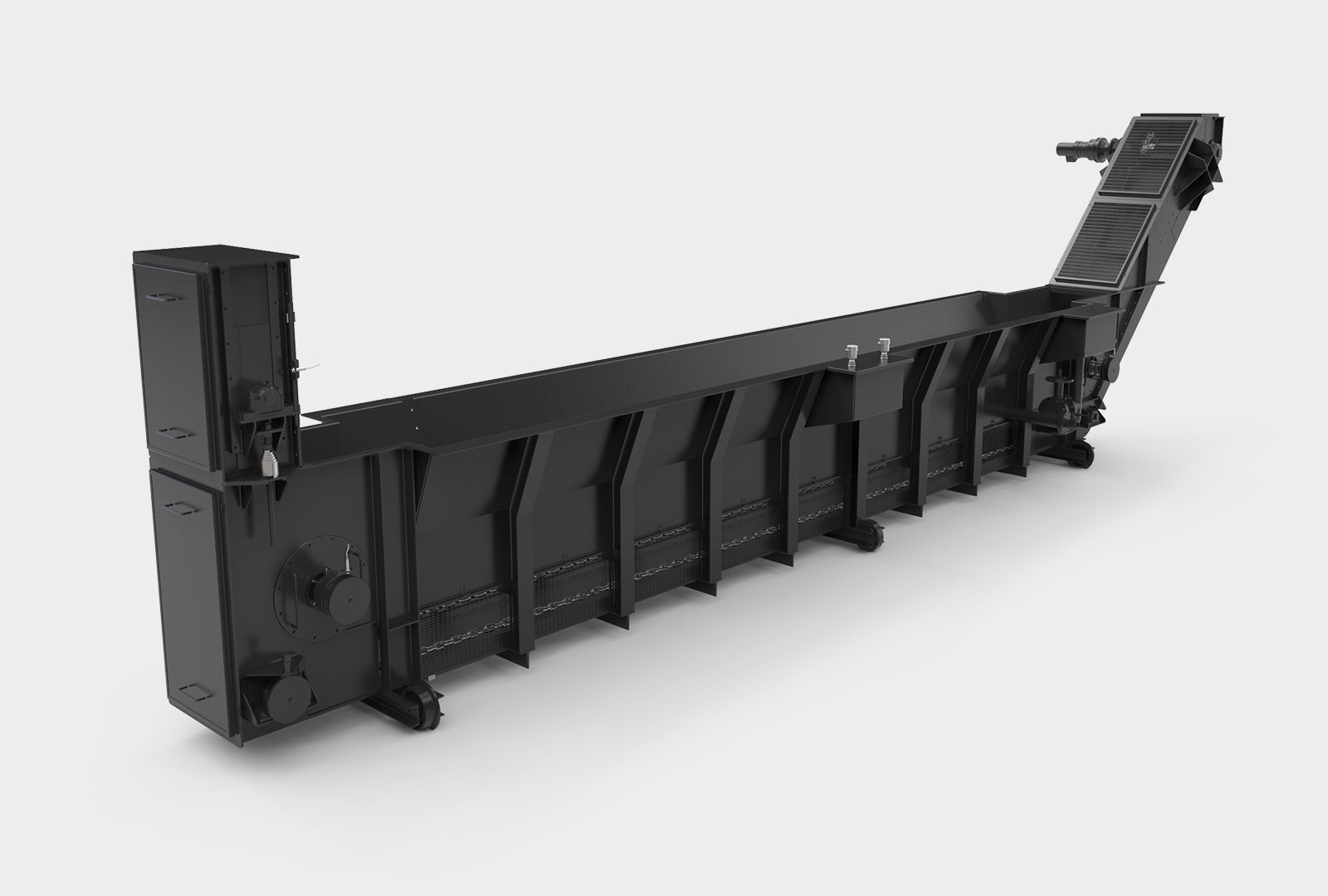

Steel Plate Conveyors

For use in mining, foundries, steel mills, metal processing, paper mills, building materials industry, glass industry, scrap processing, environmental and recycling industry. Due to the robust design, heavy materials such as stones, mixed construction waste, bulky waste, industrial waste, etc. can be dealt with.

Specifications

- Band Width up to 3,000 mm

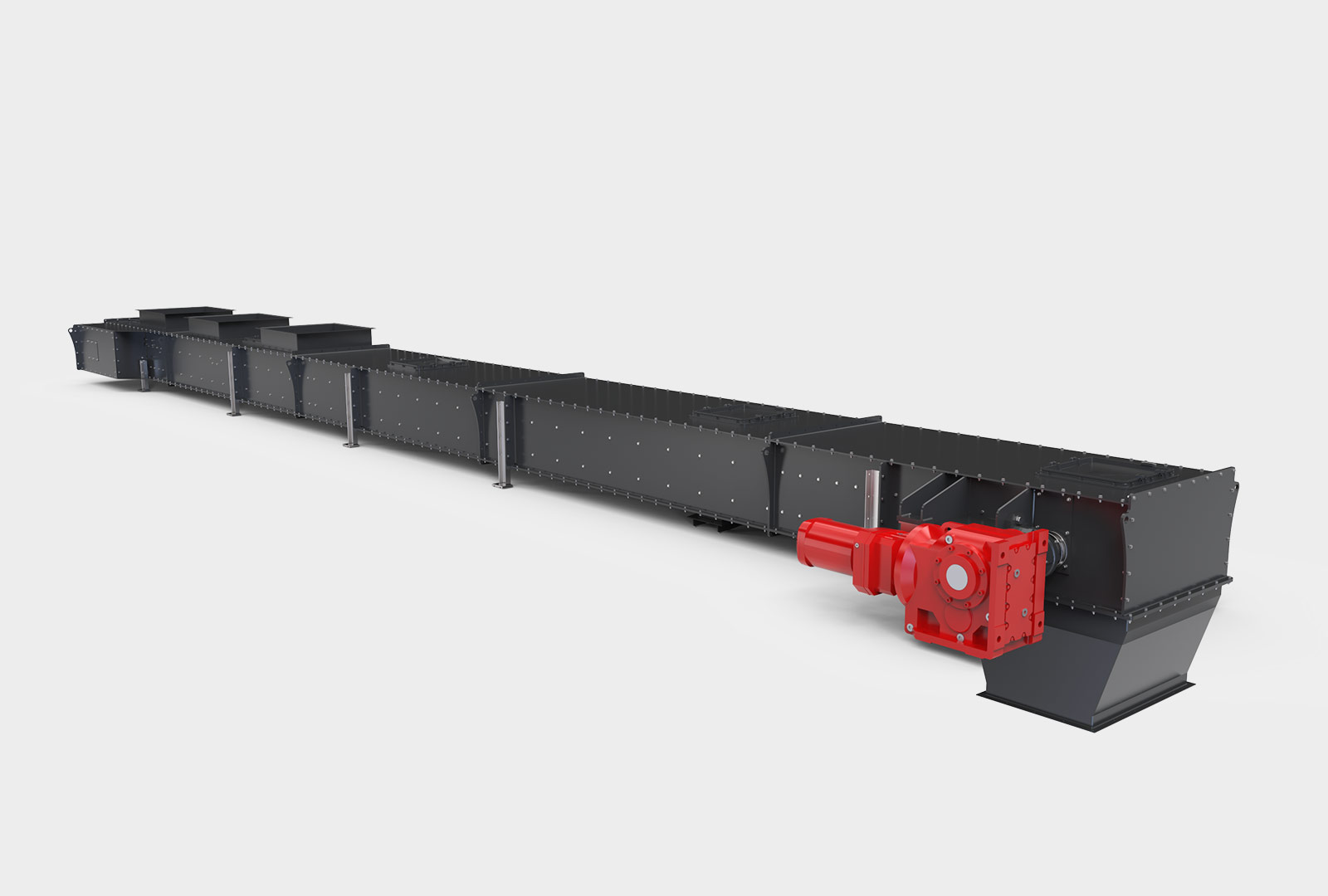

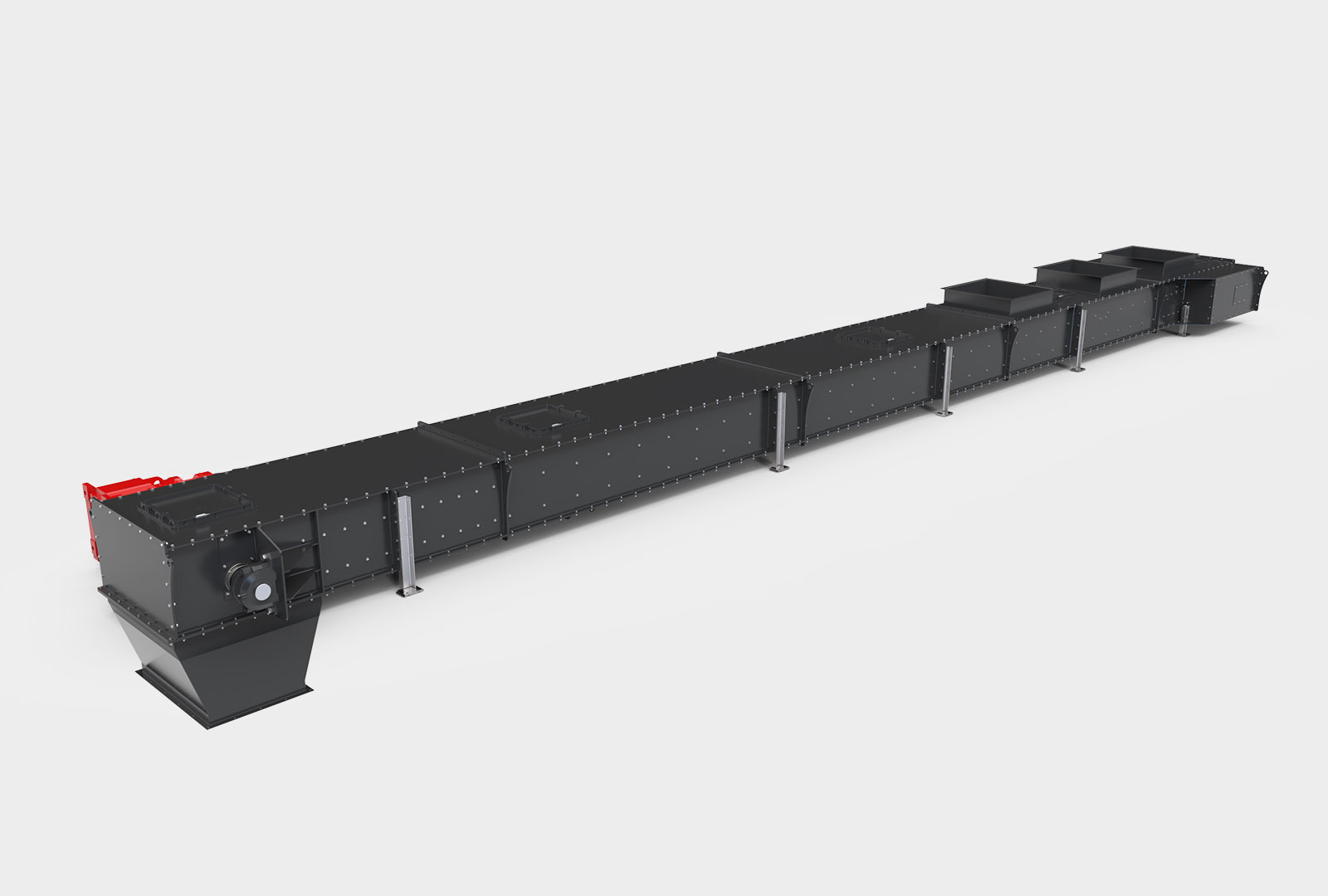

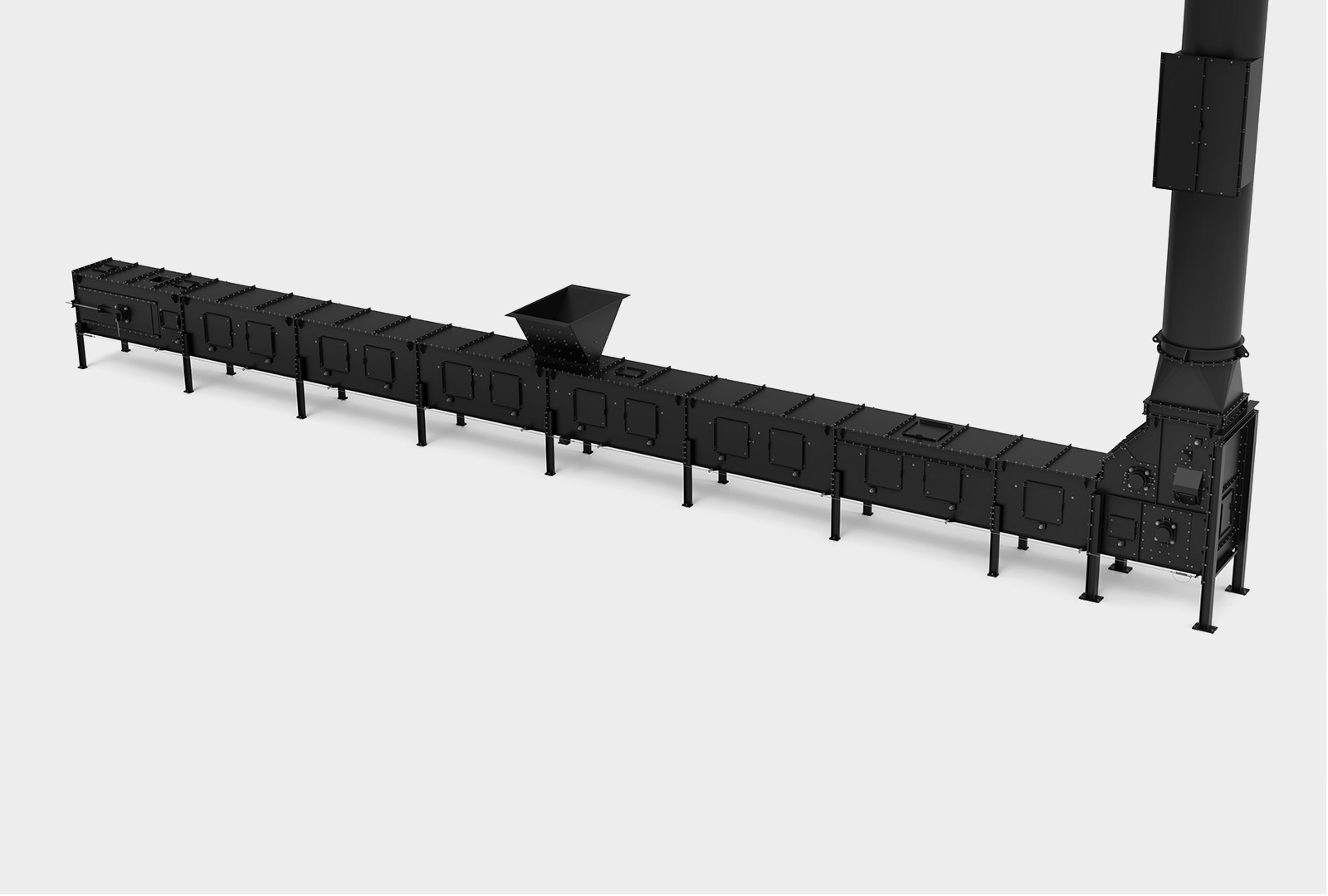

Trough Chain Conveyors

Trough chain conveyors are suitable for dust, ash, slag conveying, sewage sludge conveying, chip transport, and wood chips. Trough chain conveyors are continuous conveyors that transport bulk material horizontally, vertically or diagonally in troughs using single or double-stranded conveyor chains. IEM trough chain conveyors transport largely non-caked bulk goods. They operate dust-free, are environmentally-friendly and gas-tight and designed as shockproof and in the ATEX range. Their main advantage is the low space requirement with high flow rate.

Specifications

- Widths of 140 – 2,400 mm

- Conveying Speed 0.01 – 0.6 m/sec.

- Delivery Rate up to 1,000 m³/h

- Grain Size from 0 – 300mm

References

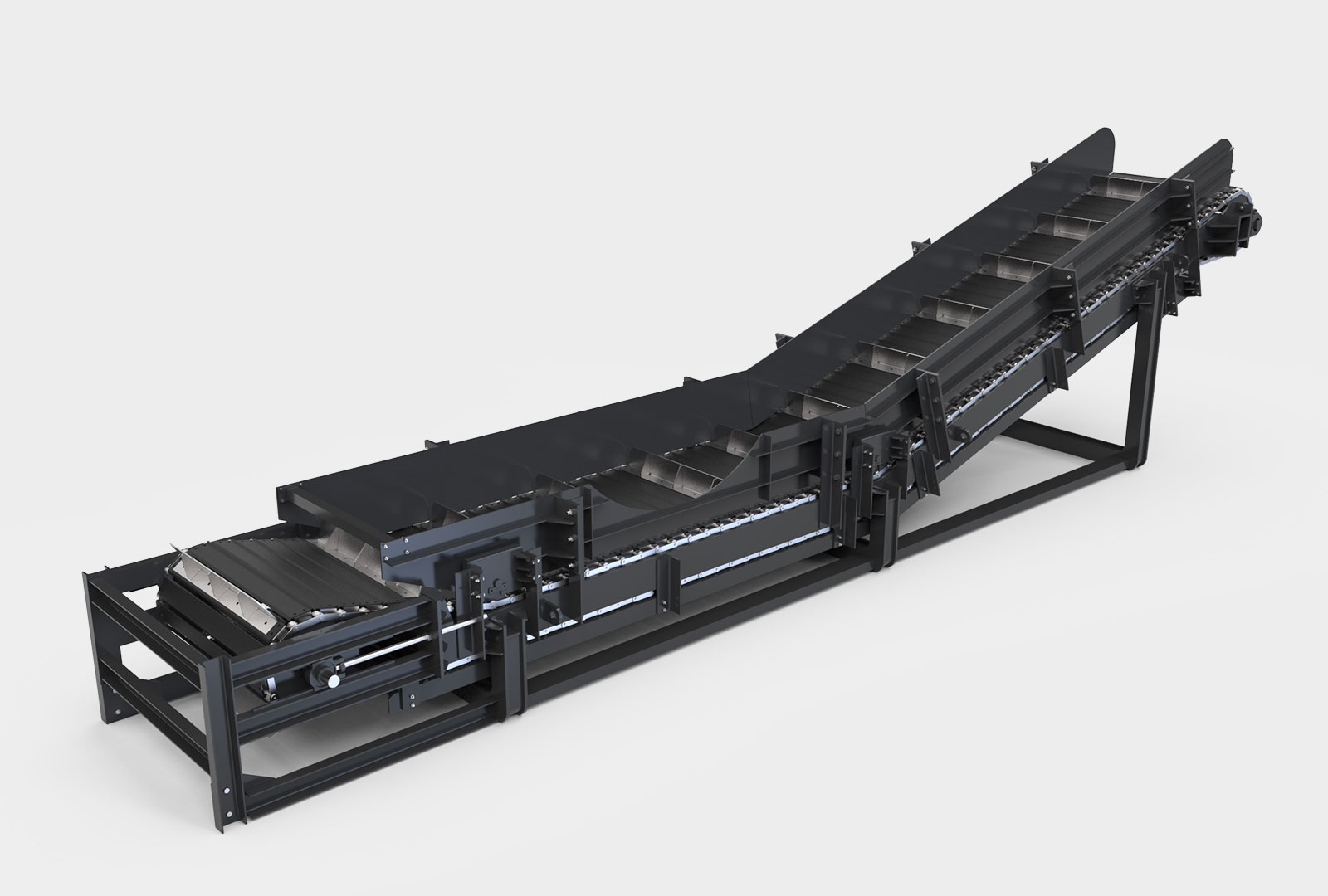

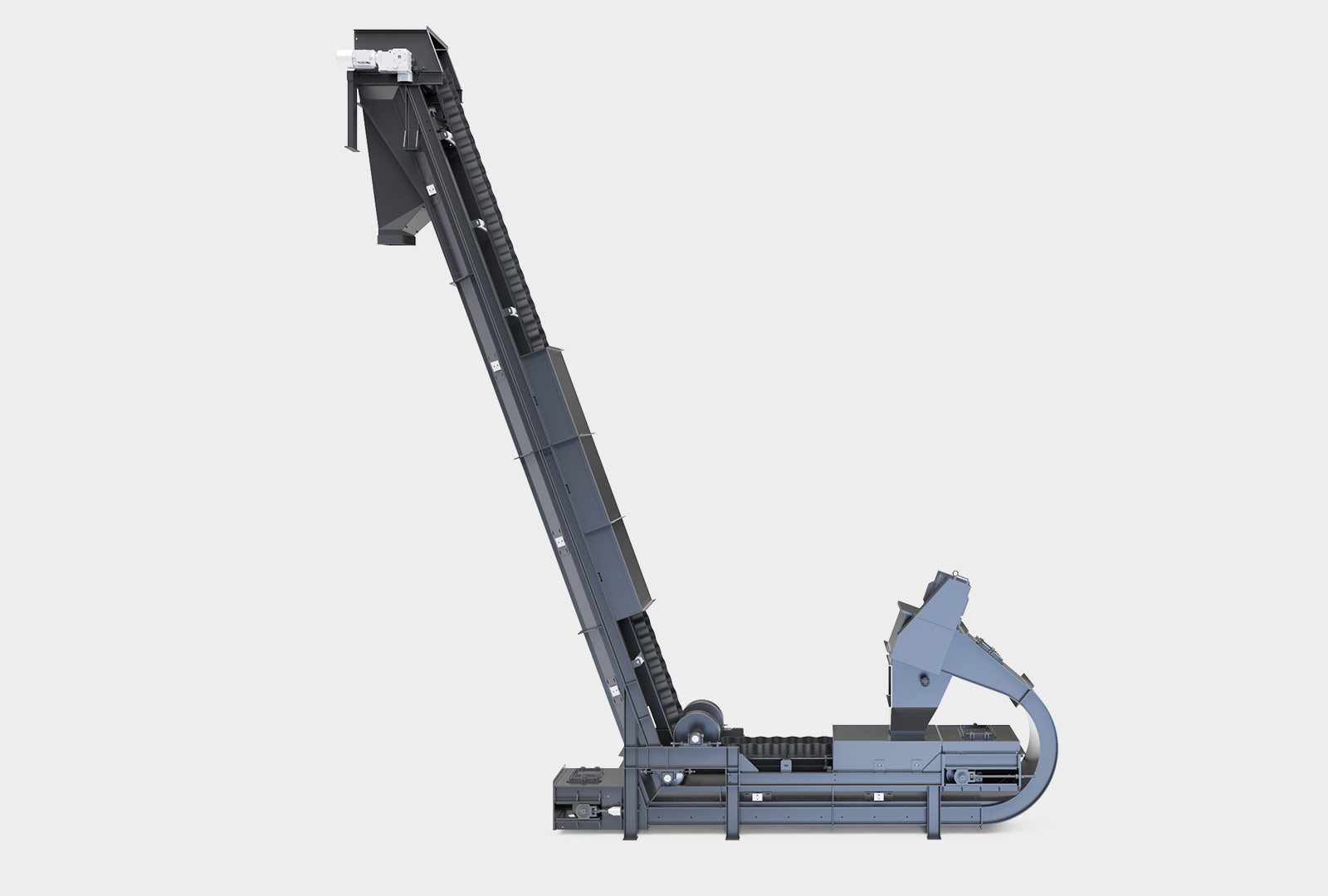

Corrugated Belt Conveyors

IEM corrugated belt conveyors support your daily tasks in the transport of minerals, coal, iron, recycled material, alloys, metallurgical additives. They are suitable for vertical and horizontal conveying (also in combination), offer solutions for angular misalignment in curved conveyors, and are low-noise in operation.

Specifications

- Belt Width: 400 – 1,600mm

- Delivery Rate: 10 – 2,000m³/h

- Gradient: Up to 90°

- Come in Various Shapes – S-shaped, L-shaped, C-shaped

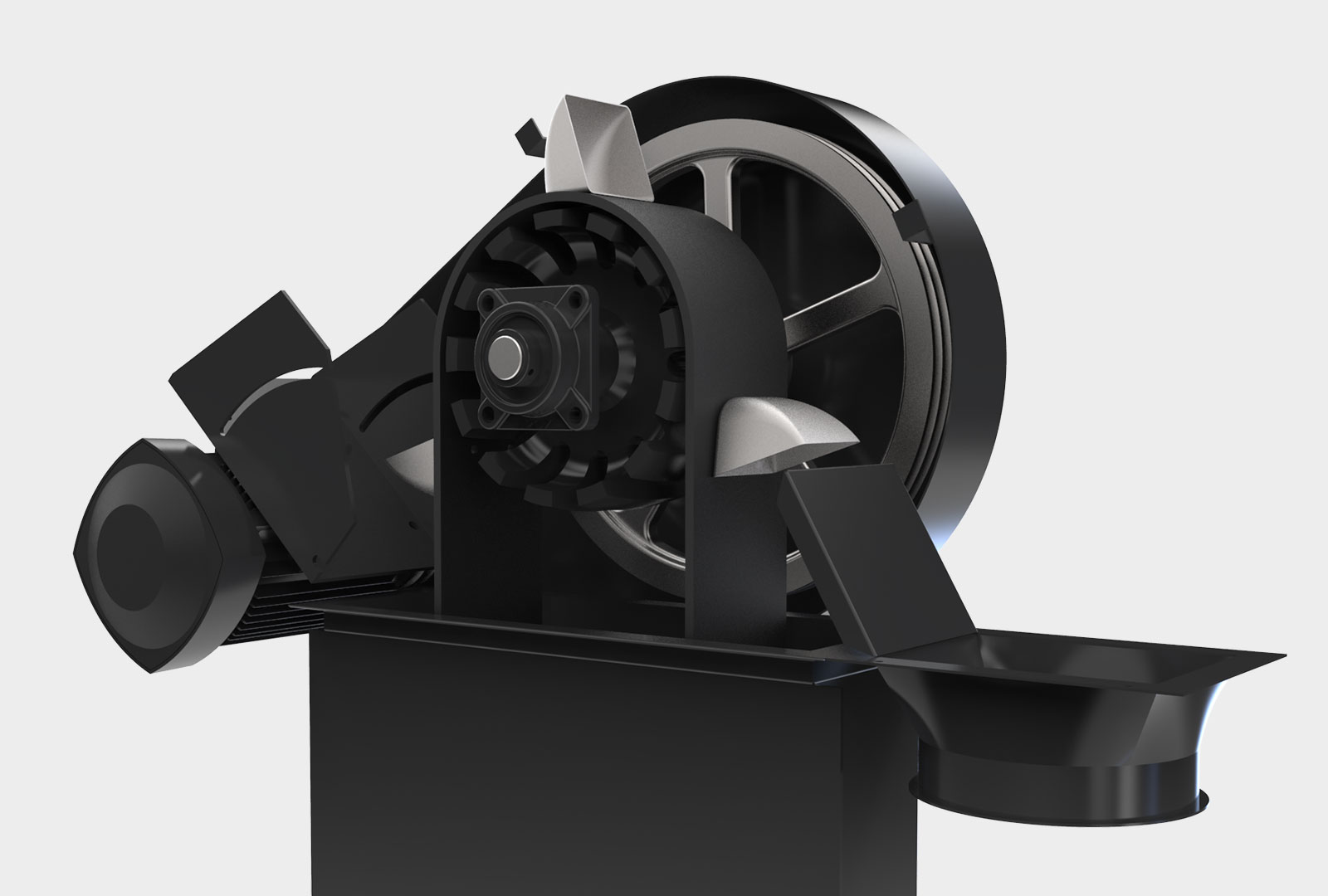

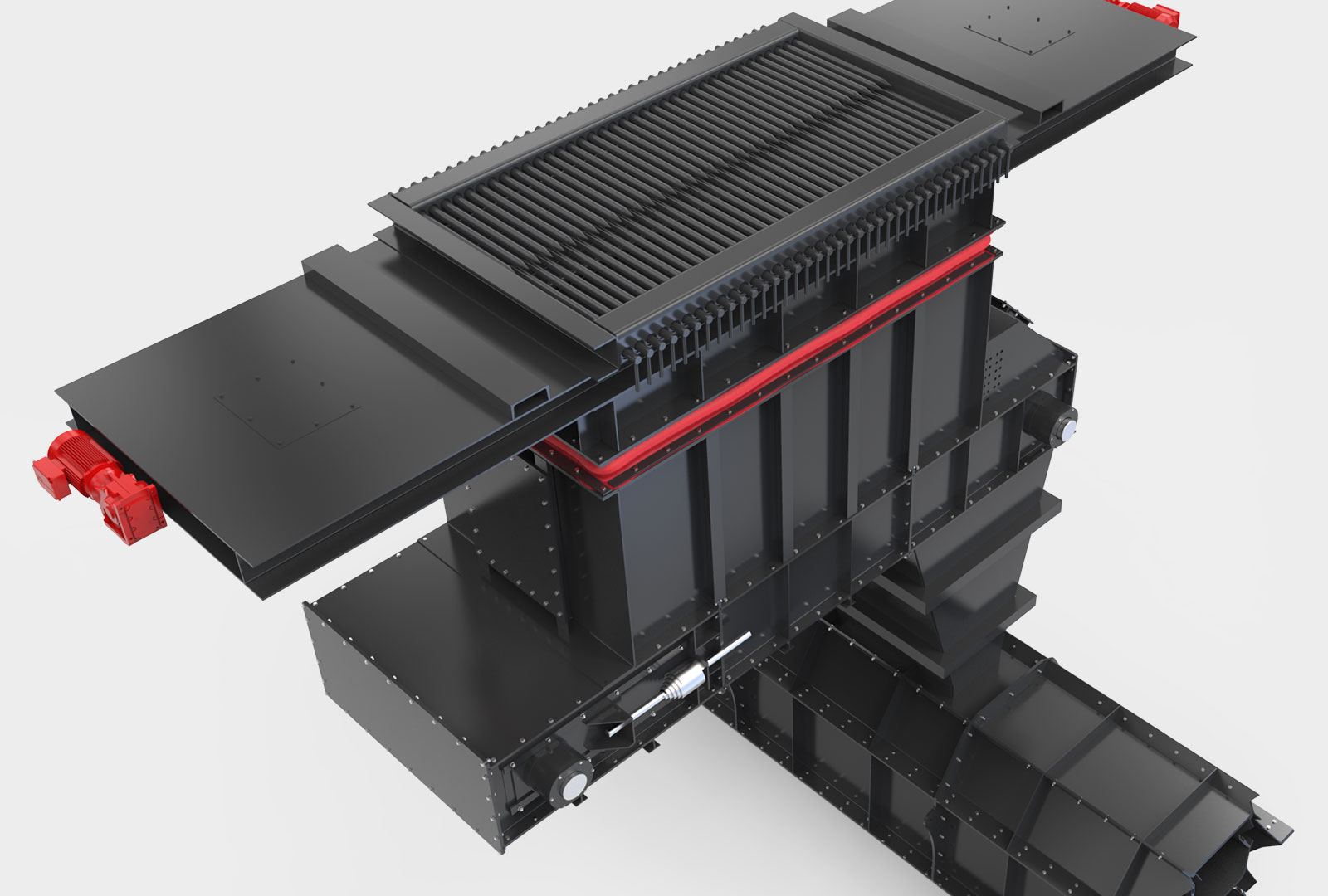

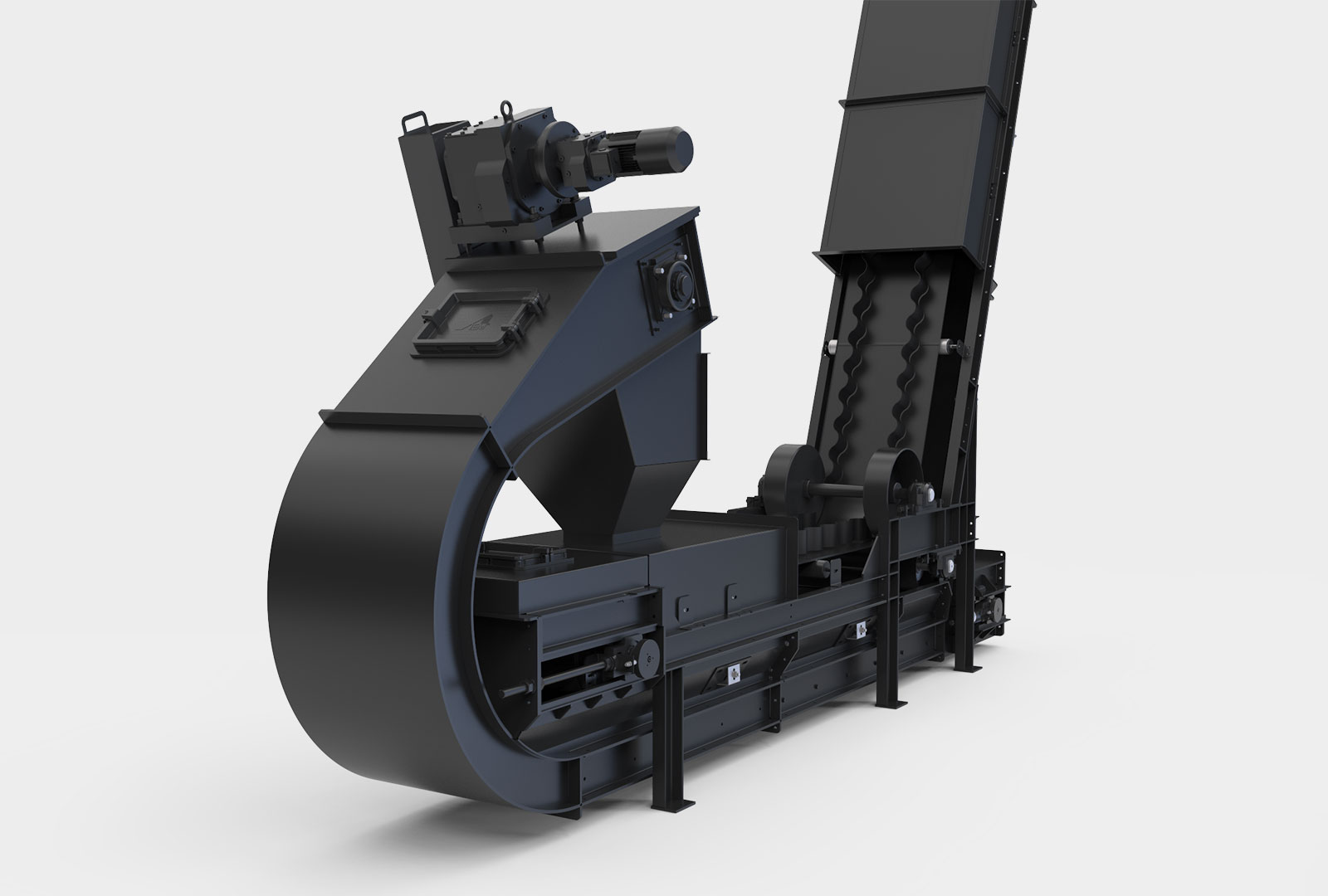

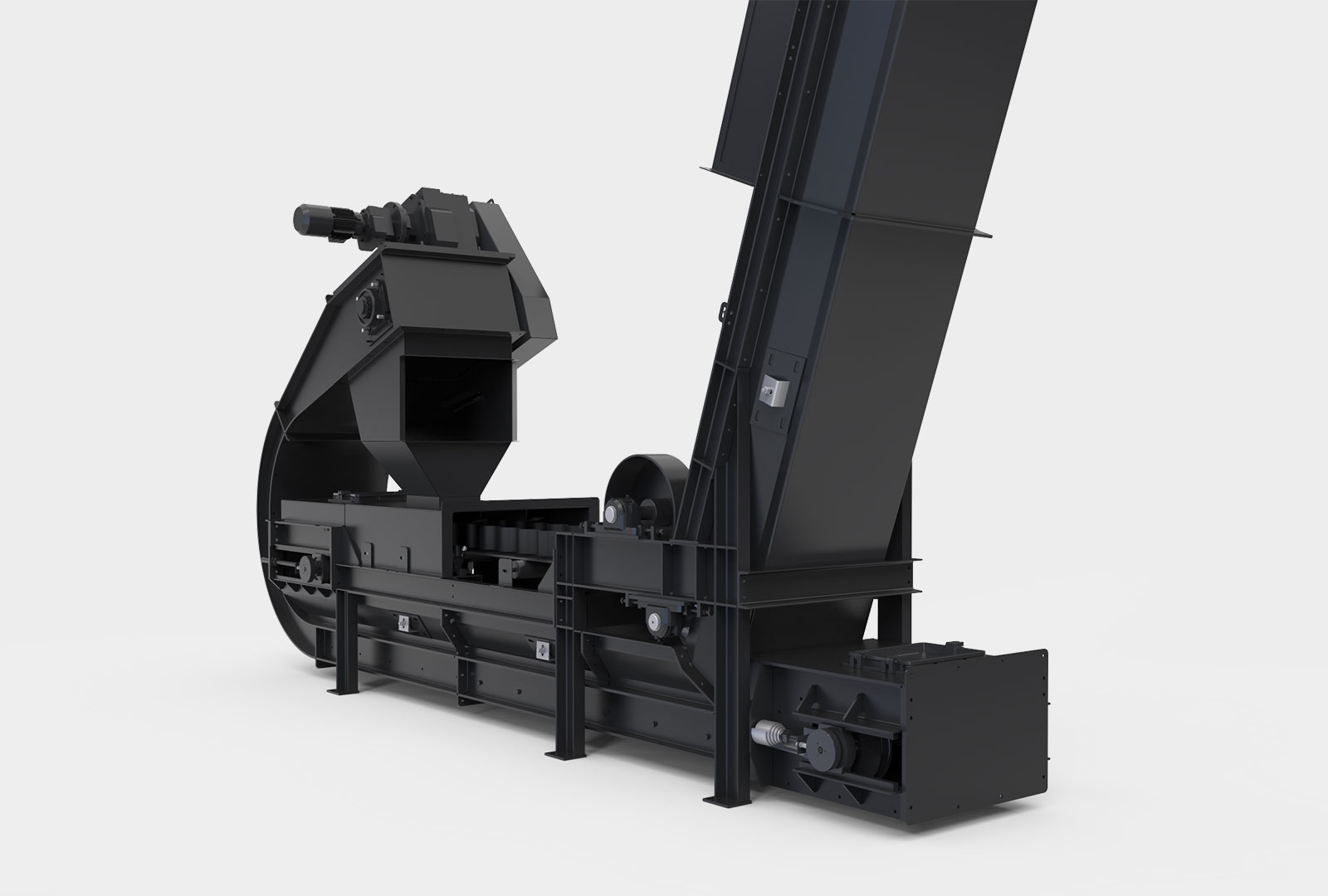

Bottom Ash Discharger

IEM Bottom Ash Dischargers are designed for slag residues which fall into the Bottom Ash Discharger at the end of the grate. These residues are cooled down with the help of a water bath. The slag chute is immersed in the water bath of the Bottom Ash Discharger to achieve an air seal to the furnace. The grate through fall that accumulates under the combustion grate is collected by hoppers and fed to the Bottom Ash Discharger via chutes. Here, too, air sealing is achieved by immersion chutes. The Bottom Ash Discharger, including the inlet and discharge cross-section, is designed to ensure trouble-free discharge of coarse slag and metal particles.

Specifications

- Specifications: 0,3 – 6 m/min

- Capacity: up to 100 t/h

- Higher capacities are also possible in accordance with the geometry and other requirements.

References

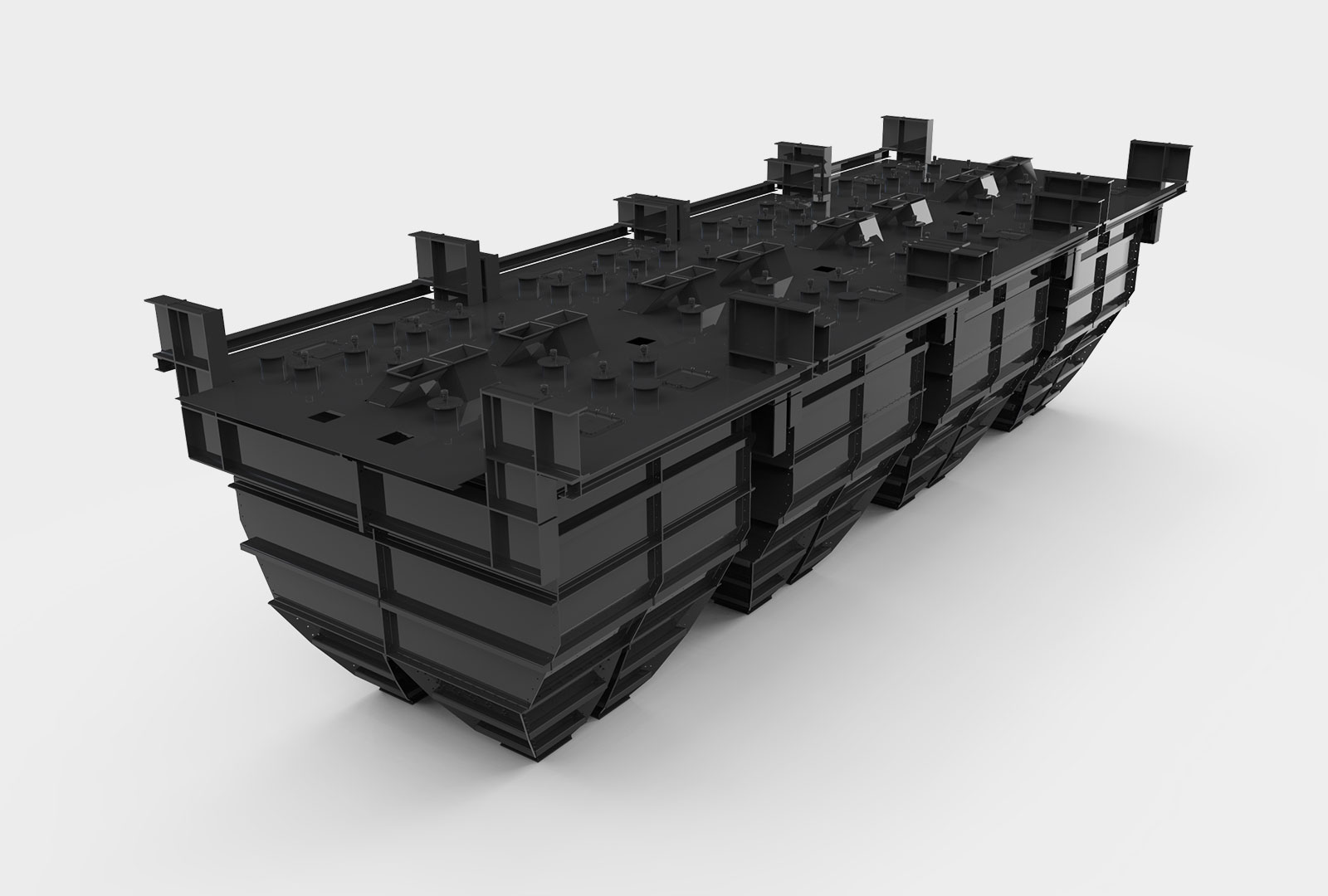

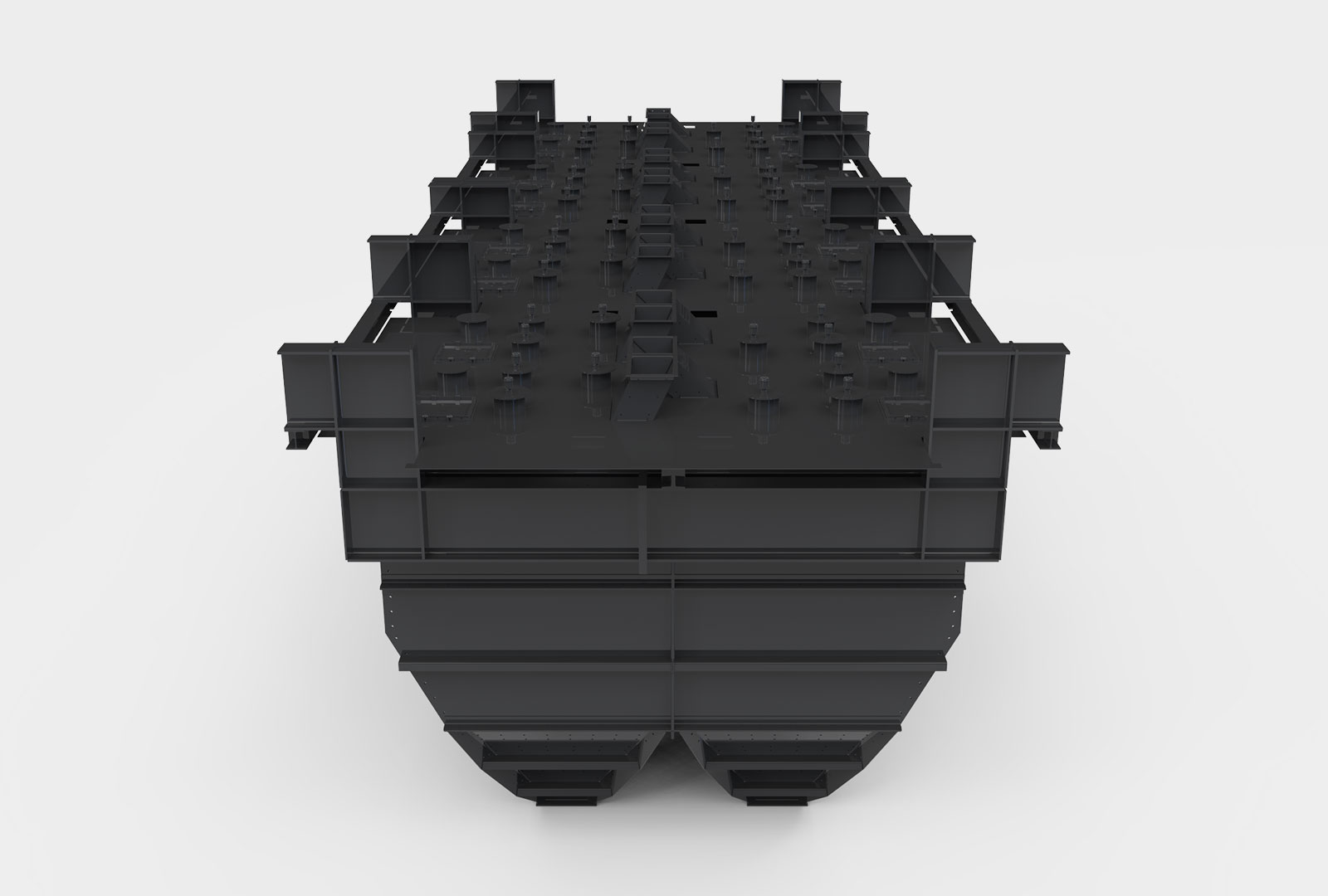

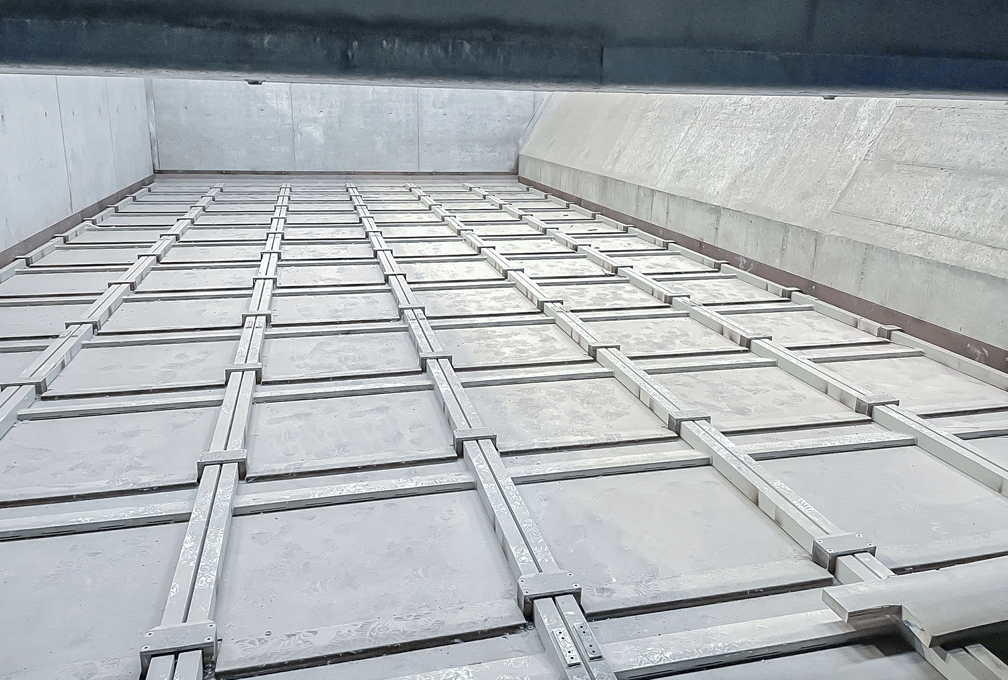

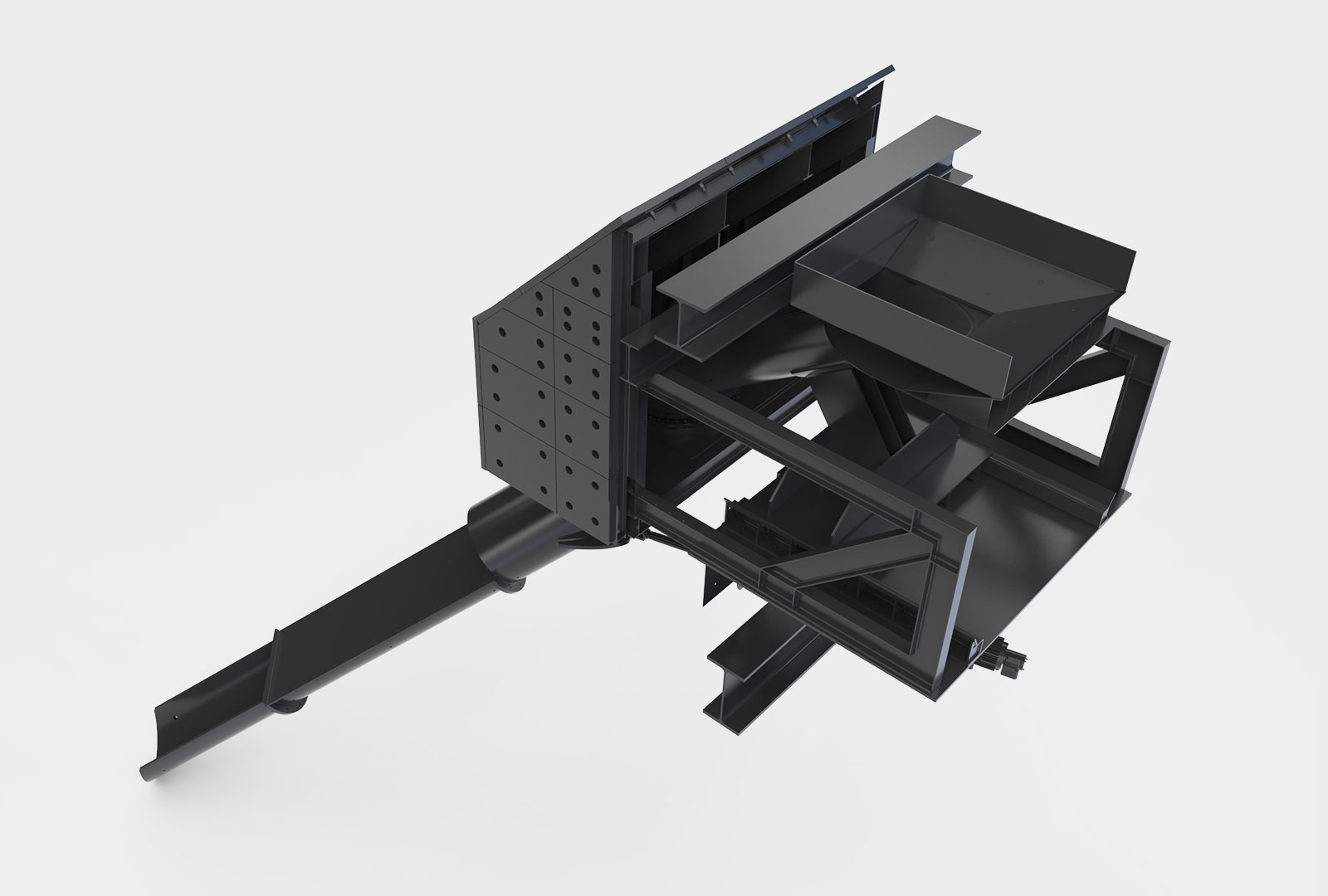

Hydraulic Push Floor

IEM corrugated belt conveyors support your daily tasks in the transport of minerals, coal, iron, recycled material, alloys, metallurgical additives. They are suitable for vertical and horizontal conveying (also in combination), offer solutions for angular misalignment in curved conveyors, and are low-noise in operation.

Specifications

- Integrable into storage facilities up to 25 meters long

- The width is limited only by local conditions due to the modular design.

- The standard filling height of up to 4 meters can be increased to approximately 8 meters depending on the nature of the conveyed material.

- The discharge capacity, depending on the conveyed material, varies between 150 and 500 m³/h per module.

- Variations:

-

- Push Floor: Guide rails push the conveyed material to the side of the bunker.

- Pull Floor: Guide rails pull the conveyed material to the side of the bunker.

- Push & Pull Floor: A combination of both systems moves the conveyed material to the center or to multiple outlets of the storage facility.

References

IEM ConveyingSystemsProducts for unit load handling

FörderTechnik offers a wide range of products and services for the realization and optimization of processes in unit load conveying technology. For decades we have been successfully designing, constructing and manufacturing for our customers. Together we analyze your logistical problem and then develop the concept for your customized transport system. Whether carton or container conveying, pallet or mesh box conveying, small parts or large parts conveying, intralogistics material flow or load carrier management, only when you are convinced of our concept do we start with the offer phase. From the first hour of construction to project management, we are always at your side with help and advice. Take advantage of our production-technical know-how, because that’s what distinguishes the ROS FörderTechnik team. Qualified employees of IEM FörderTechnik are your contact in all phases of the progress. Our in-house production with modern machinery enables us to react flexibly and competently to the most diverse requirements. We support your solutions! It’s not only about selling individual products from the catalog, but it’s about taking interest in you. Our special solutions MultiTrans, PowerTrans, ChargeTrans and NuclearTrans transport your product in the true sense of the word. There are always different approaches to logistical problems. Our focus lies exclusively in the sensible movement of your goods and merchandise, whereby we are also happy to take the unconventional and creative path.

PowerTranS

IEM PowerTrans is a driven conveyor system in the field of unit load conveying, which is manufactured according to customer-specific requirements.

Here we also like to take the unconventional and creative way and ensure an efficient flow of goods.

This product portfolio includes the complete conveyor repertoire such as roller conveyors, chain conveyors, rotary tables, lift and lift-out stations, etc.

Characteristics

Customer-specific container handling

Sturdy construction with high load capacity

Driven and non-driven conveyor technology

Stationary conveyor technology combined with driverless transport system

Transport of fragile goods

Transport in all directions

High flexibility of the transport modules

ChargeTranS

The IEM picking trolley solution System ChargeTrans brings structure into your workspace.

Developed as a logistic picking system, IEM offers with ChargeTrans an ergonomic handing of your provision goods in the area of goods to man, to customer and from point A to B.

The picking trolley is customized according to your requirements and adapted to your flow and cycle assembly.

Characteristics

Customized development up to the application

Sturdy construction with up to 1 t of load capacity

90 kg of its own weight

Weight and load optimized

Variable transport and conveyor capability (skids or rollers)

Applicable for various load securing systems

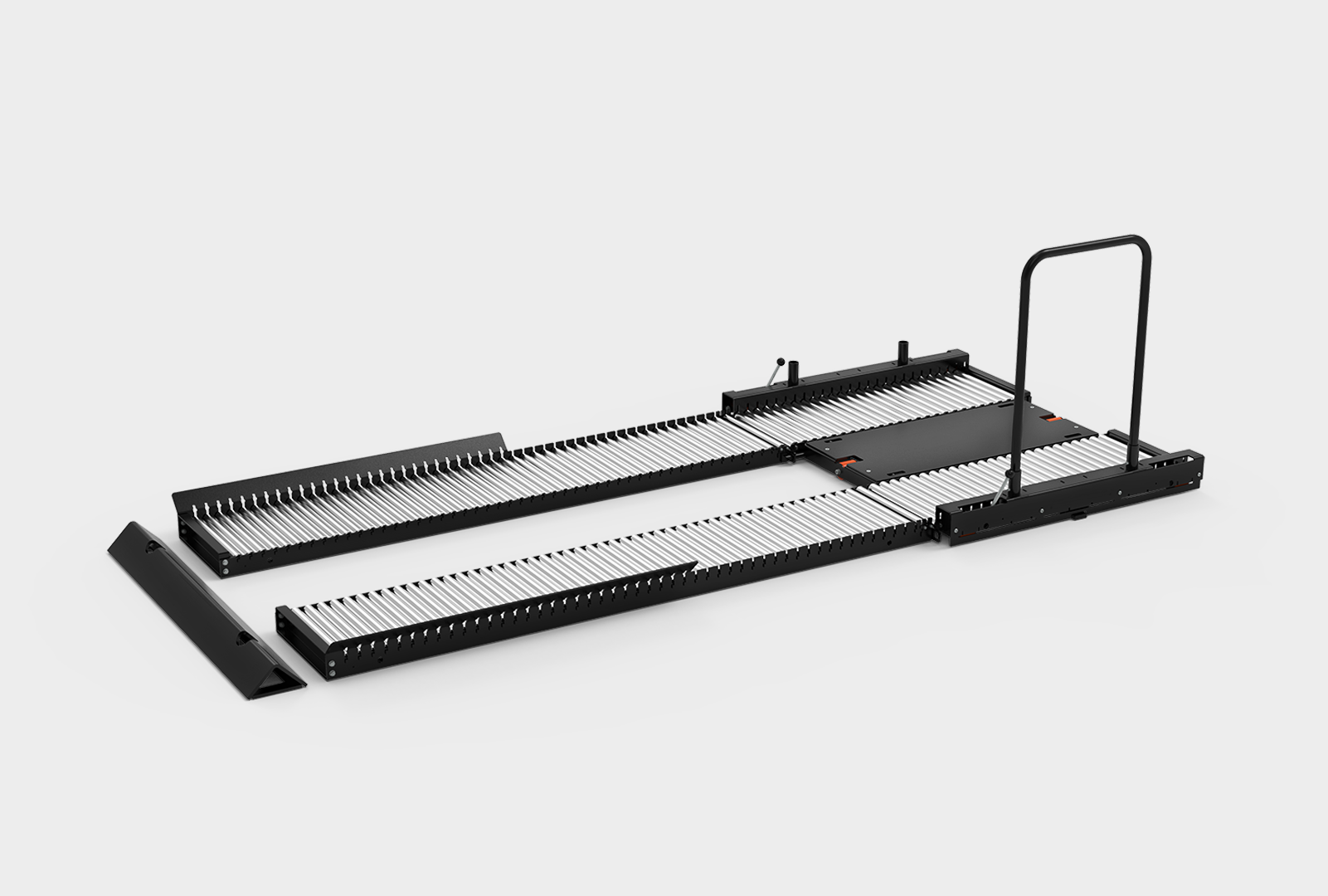

IEM pallet roller conveyor MultiTrans

Non-driven roller conveyor solutions for continuous transport or availability of a large number of load carriers.

Due to the small roller distance is ROS MultiTrans compatible with countless bases, runners and supports and offers countless loading options.

The roller conveyors can be individually combined due to their standardized, modular design and grow with the requirements.

Characteristics

Cost-effective supplement to driven conveyor technology

Suitable for all light or heavy load carriers up to 2.5t

Lowest installation height from 62mm

Modular design with standard lengths from 1500mm to 2000mm

Optional raised or possible in elevated version

NuclearTranS

NuclearTrans are conveyor systems that fulfill the special demands of the nuclear sector and decommissioning. By using automated conveyor systems, physically heavy work and the radiation exposure of the employees can be minimized.

Characteristics

Customer-specific container handling

Sturdy construction with high load capacity

Driven and non-driven conveyor technology

Stationary conveyor technology combined with driverless transport system

Transport of sensitive/fragile goods

Transport in all directions

High flexibility of the transport modules

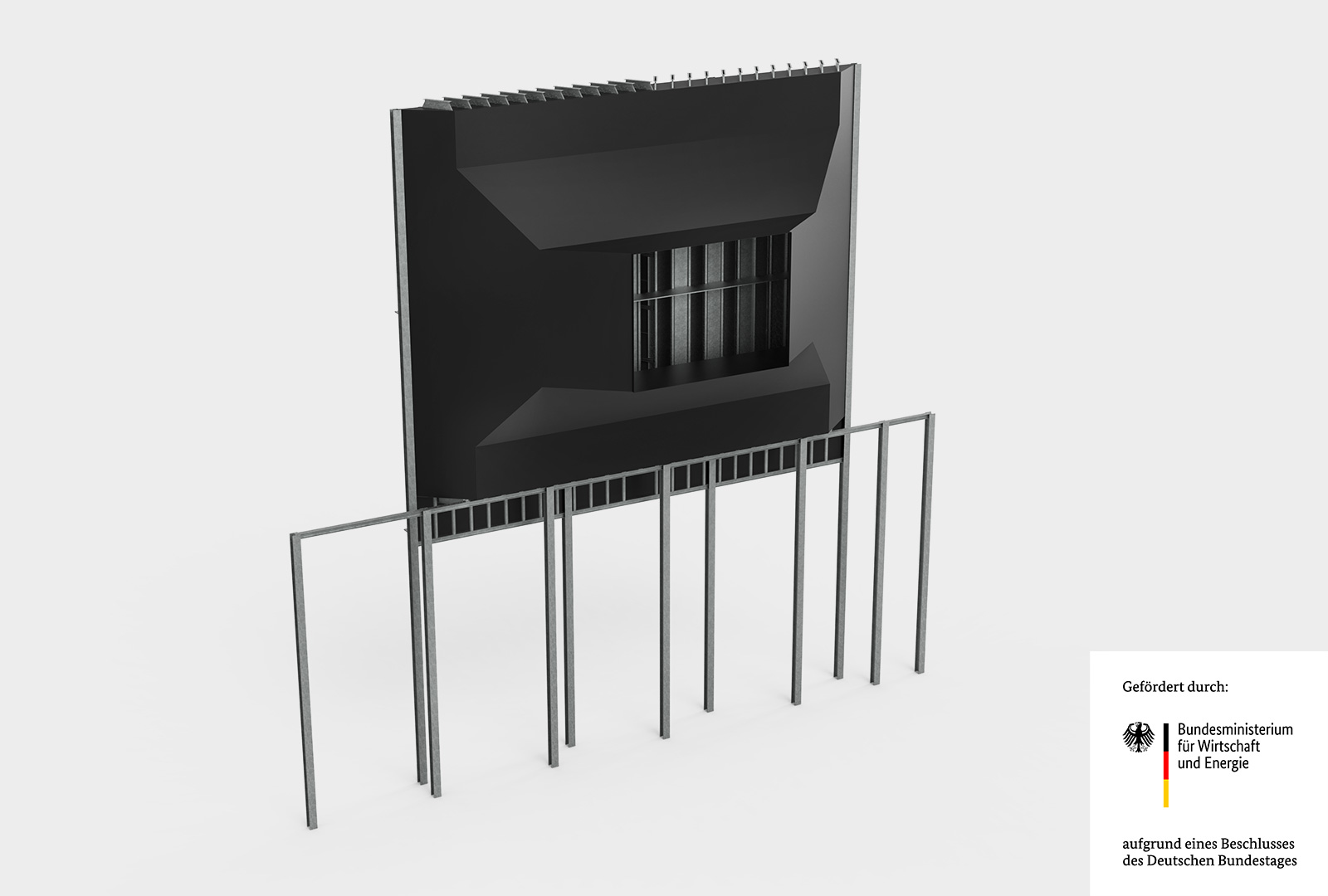

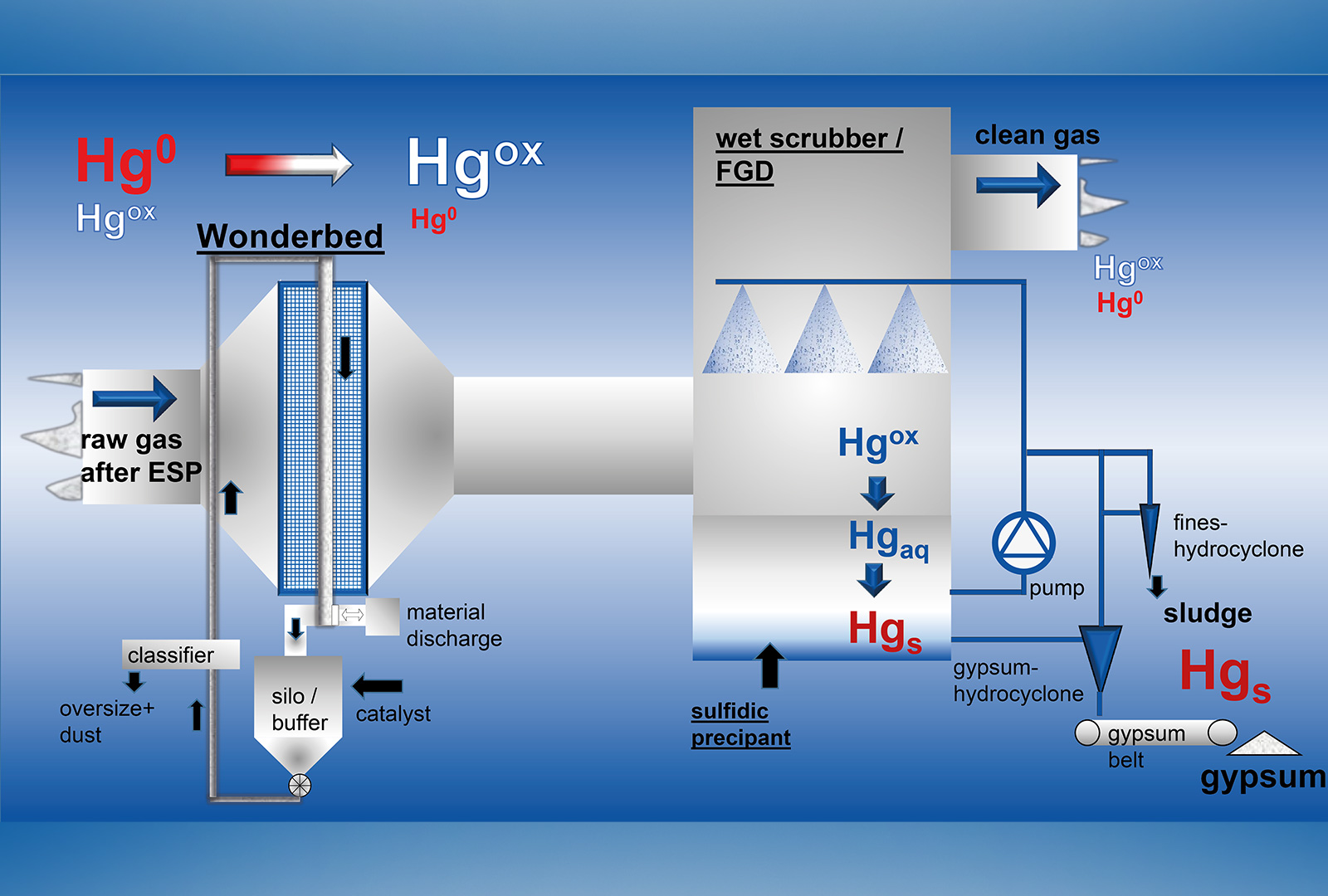

Wonderbed-Filter

IEM Wonderbed-Filter is a new process technology for catalytic mercury oxidation.

It is recommended, to install the filter behind the dust filter, in order to avoid unnecessary blockages of the continuously circulating catalysator bed. Due to the narrow bed geometry, it can be directly integrated in the outlet zone of already existing electrostatic precipitators (retrofit option). A mobile demonstration plant can show you the suitability to your local process conditions. The filter geometry can be flexibly adapted by arranging several filter lines in parallel.

The IEM-Wonderbed is an EU research project, funded by: Federal Ministry for Economic Affairs and Energy based on a resolution of the German Bundestag.

Characteristics

Achievable mercury oxidation rates: up to >95 % possible

Exhaust gas volume flows: 2,000 – 2,000,000 m³/h

Pressure drop: 1-6 mbar

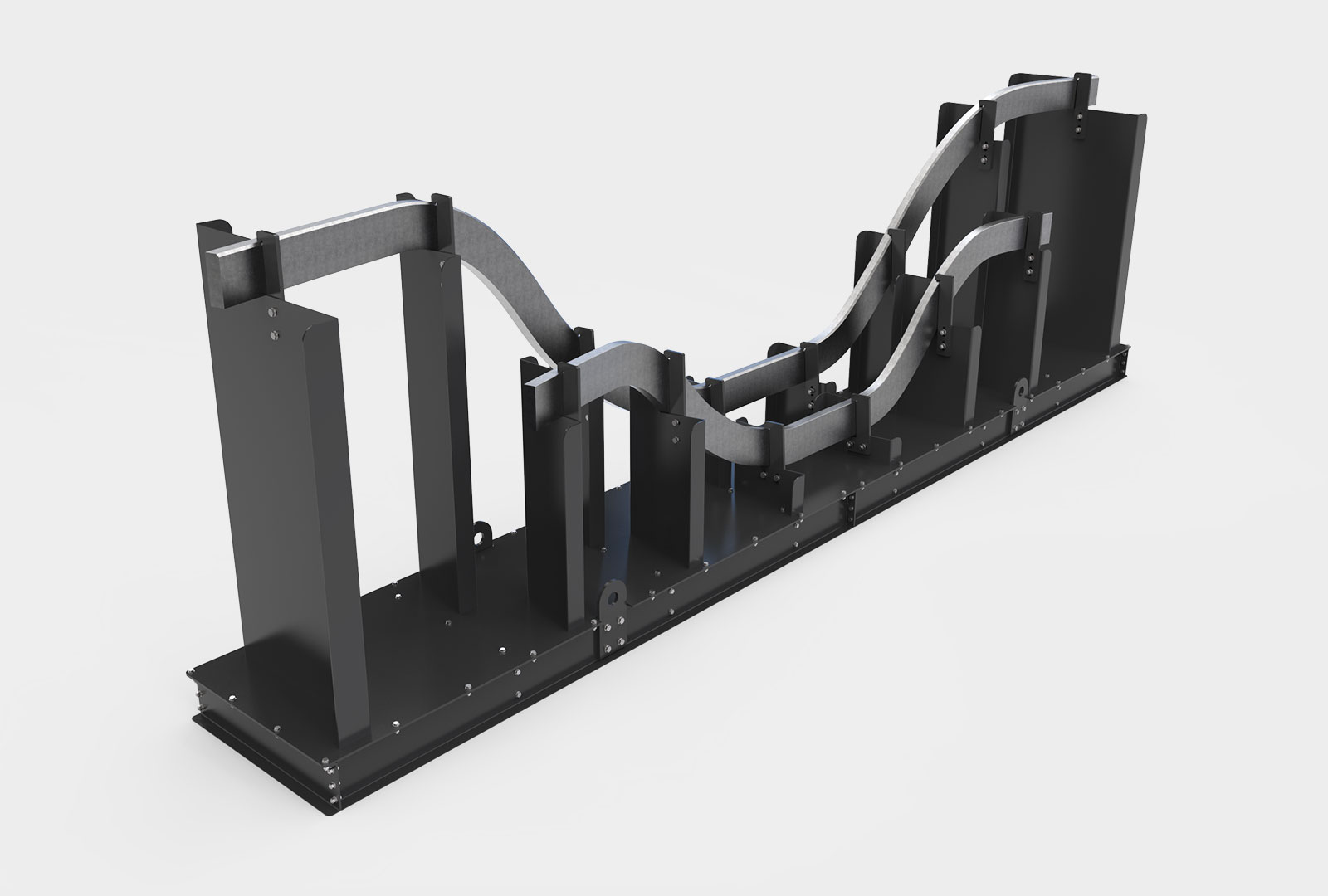

Lowering Rails

In rotating sinter coolers, sintered material is moved on a dolly in a closed circle. In continuous operation, the cars are driven over the lowering rails at the end of the cooling section and emptied. The highest accuracy and durability are required for this application. The complex geometries of the rails are produced in a multi-stage forming process.

Swing Chutes

For uniform filling of containers and other storage units, IEM swing chutes are available. Each IEM swing chute can be adapted to local conditions and operated manually, electrically, pneumatically or hydraulically.