Since August 2018, stricter mercury emission limits (range 1-7 µg/Nm³) are expected for coal combustion from the implementation of the BREF documents into German law.

If the lower limits are pushed, this will be associated with capture rates of 80-95% at lignite-fired power plants, for example. Such a high reduction potential is not achieved by the usual processes (AK entrained flow process, halide addition to the furnace).

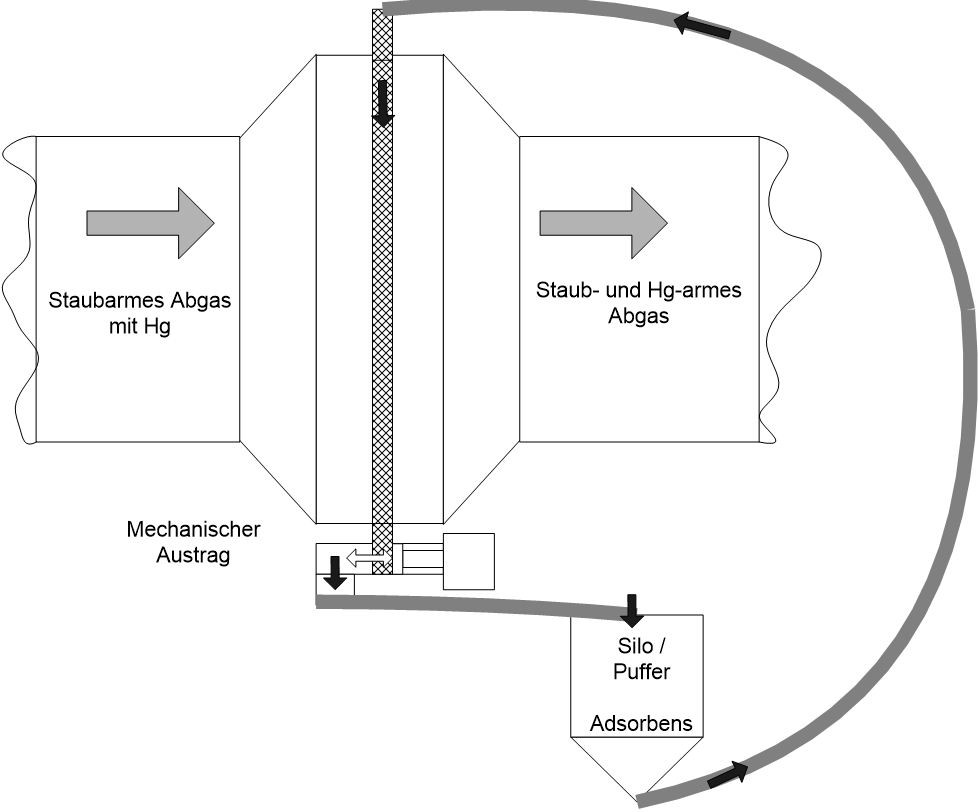

Therefore, IEM Fördertechnik GmbH in cooperation with Steinmüller Engineering GmbH has developed a solution approach for high separation efficiencies. The Hg-containing waste gas is treated in a narrow, modular filter system. The filter material is moved continuously (fluidized bed process) to avoid sooting and hot spots (fire hazard). Thanks to the low pressure drop of <10 mbar across the bed, the technology is also suitable for retrofitting to existing plants. The specific selection of the materials used determines whether a separate Hg sink (adsorption mechanism) is created or the separation should take place, for example, in the downstream wet scrubber (catalysis mechanism). In the case of adsorption, the maximum Hg loading of the materials used can be exploited. However, depending on the input material, the new technology also offers the potential to separate not only Hg but also other heavy metals, dust and SO2 in the circulating filter layer. Thus, the technique is also transferable to flue gas cleaning downstream of other firing processes e.g. sewage sludge, waste incineration, metallurgy. In order to better understand the separation mechanisms and the operational variables influencing the new technology, a test plant will be operated in continuous operation at the Schkopau power plant from March 2020. At around 50,000 m³/h, the exhaust gas volume extracted for treatment here comprises approx. 2 % of the total exhaust gas flow of the coal-fired unit. Continuous test operation is planned until the middle of 2021.

+ Hg reduction >90 % achievable

+ Catalytic Hg0 oxidation can also be used by selecting the right material

+ low adsorbent consumption compared to activated carbon entrained flow process

+ low operating costs

+ through material adaptation also usable for the separation of other volatile pollutants

+ modular cassette design / material selection enables increase of separation efficiency

+ suitable as retrofit

+ flow equalization for upstream / downstream plant components

– Moderate pressure drop (<10 mbar)

– Generation of separate waste stream (Hg-enriched)

– Handling of combustible materials

– No large-scale references so far

The IEM-Wonderbed is an EU research project, funded by: Federal Ministry for Economic Affairs and Energy based on a resolution of the German Bundestag.