Activated carbon acts like a sponge: it absorbs toxic substances, which can later be easily removed together with the activated carbon. Thanks to this process, the lignite-fired power plant in Schkopau will reduce its mercury emissions by two-thirds and thus comply with the new limit value.

Too valuable to burn: activated carbon is used in medicine, wastewater treatment and power plants (Photo: Self, CC BY-SA 3.0)

Anyone who has ever set up a campfire knows the process well: wood burns and loose black pieces remain: Carbon charcoal. Activated carbon is produced in a very similar way, with one crucial difference: the oxygen supply is cut off. So instead of burning the wood, it chars. What remains is a material that contains a lot of carbon. This can be activated with water vapour or carbon dioxide – that’ s it, the activated carbon is finished.

Charcoal making is an old craft in which wood is burnt under oxygen exclusion to produce charcoal. However, the temperatures are lower: charcoal is produced at around 275 °C, activated charcoal at 500 to 900 °C. In addition, activated charcoal must be chemically activated.

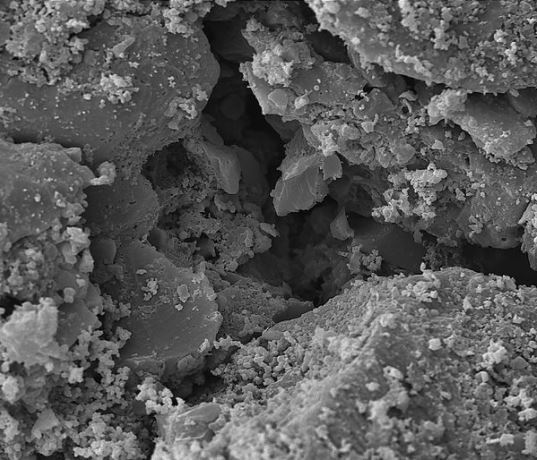

Aktivkohlepellets unter einem Rasterelektronenmikroskop (Foto: Mydriatic, CC BY-SA 3.0)

Aktivkohlepellets unter einem Rasterelektronenmikroskop (Foto: Mydriatic, CC BY-SA 3.0)The inner surface of 4 grams of activated carbon is about the size of a football field. That is because it has an extremely large number of pores, as can be seen in the graphic on the right. This enables the activated carbon to easily absorb and bind gases and liquids. We benefit form this in many everyday circumstances – often without even knowing it. Activated carbon is found in insoles for shoes, which are supposed to absorb annoying odours, and also in cigarette filters, air conditioners and cabin air filters of cars. It even provides valuable support in the treatment of waste water.

Translated with www.DeepL.com/Translator (free version)

When electricity is generated in coal-fired power plants, toxic mercury is released. It initially flies along in the flue gas and must be prevented from simply being released into the atmosphere. From 2019, the limit value will be 10 micrograms per cubic metre as an annual average

Im Kraftwerk Schkopau baut die Firma IEM Fördertechnik deshalb eine Anlage (Bild rechts), die mithilfe von Aktivkohle das Quecksilber aus dem Rauchgas filtert (mehr Informationen zum Projekt in Schkopau finden Sie hier).

Step 1: Delivery and storage of the activated carbon

Once or twice a day, a truck delivers the activated carbon. The dusty mass is stored in the two green storage tanks.

Step 3: Mixing with the flue gas

The air-activated carbon mixture enters the flue gas duct through several nozzles. The mercury sticks to the activated carbon particles – like to a magnet.